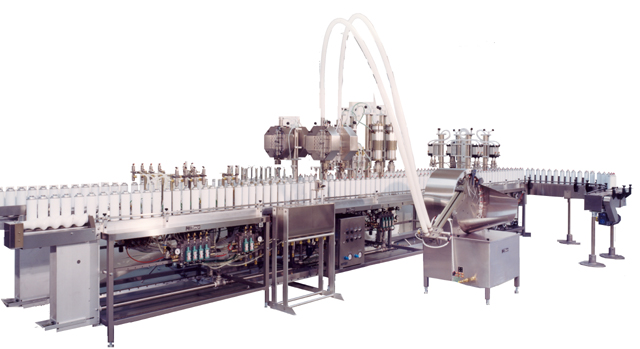

DL Series Inline Indexing Machines

Double lane indexing filling machines for the production of aerosol products up to 140 cans per minute.

The Model DL Double Line filling system has become an industry standard in inline filling. The machines feature all pneumatic control logic to address hazardous environment concerns while providing an easy to use system for maintenance issues. The drive system features adjustable guiderailing to allow all of the standard aerosol containers to run on the system without the need for additional changeparts.

The systems can be configured in either Double Line Single Indexing (DLSI) with speeds up to 80 cans per minute, or Double Line Double Indexing (DLDI) with speeds up to 140 cans per minute. With single indexing systems, the tables can be pre-drilled for a future upgrade to double indexing to meet future capacity needs.

The bases are constructed from epoxy-coated structural steel and are covered with a polished stainless steel top. Stainless steel manifolding is standard. Some of the available options include safety enclosure, lower stainless steel panels, and sanitary/dairy construction.

All of the standard stations can be outfitted to the base to meet the exact requirements of your filling process.