Understanding The Bag on Valve Aerosol Filling Machine

Bag on Valve (BoV) technology has revolutionized the aerosol packaging industry. This ground-breaking technology changed product packaging by fusing sustainability and convenience.

But what makes BoV unique? Picture your product securely enclosed in a pliable bag that is fastened shut with an advanced valve. This clever filling method ensures that your products reach customers in perfect condition by improving product protection and extending shelf life.

BoV has a striking effect on manufacturers. Modern bag on valve filling machines allow businesses to package a wide range of products, from pharmaceutical wonders to personal care wonders, with ease.

Still, that’s not all! Businesses that embrace the bag on valve filling machine also embrace sustainability, which is important to today’s consumers. By partnering with environmentally friendly packaging options, your business attracts customers and makes a splash in a market that is eager to buy green products.

Join the leaders in the industry and make a splash with this alluring, innovative, and ecologically beneficial method by embracing the future of aerosol filling. The bag on valve filling process has revolutionized aerosol packaging.

Advantages of Bag on Valve Aerosol Filling Machine

- Bag on Valve (BoV) packaging provides maximum product protection with an extended shelf life. Manufacturers looking to preserve the quality of their products finds this technology advantageous.

- BoV technology is an eco-friendly option. It has a significantly smaller environmental impact than traditional aerosol packaging, demonstrating a commitment to environmental responsibility.

- The valve filling machine’s bag ensures accurate product dispensing, making controlled dispensing simple and reliable. This improves user experience and lowers product waste.

- BoV is a versatile packaging solution. It is used in a wide range of consumer products, including food, pharmaceuticals, personal care and household items.

- The bag on valve aerosol filling machine packaging conforms to strict regulations and safety standards. It ensures consumer safety and product integrity. Manufacturers are adopting the bag on valve filling machine due to its efficacy.

- Modern bag on valve aerosol filling equipment can help businesses improve productivity, expedite the manufacturing process, and meet customer expectations more rapidly.

- Producers can improve product performance and quality with the bag-on valve filling machine, which will increase customer satisfaction and brand loyalty.

- The sophisticated technology of the valve filling machine’s bag guarantees accurate and airtight valve crimping, which is essential for preserving product freshness and averting leaks.

- BoV packaging is a packaging method that give consumers’ growing demand for sustainable and eco-friendly packaging options.

- Manufacturers using bag on valve packaging obtain a competitive advantage in a fiercely competitive market by providing innovative, aesthetically pleasing, and eco-friendly solutions.

- The bag on valve filling machine revolutionizes packaging and offers producers and consumers a number of environmentally friendly advantages. It is popular for a range of products due to its extended shelf life, reduced environmental impact, precise dosage, and regulatory compliance.

- Manufacturers may embrace sustainability and technical improvements while preserving product quality and successfully satisfying client demands by investing in the bag on valve aerosol filling machine.

Contact Us for more information about our Bag On Valve Aerosol Filling Machines

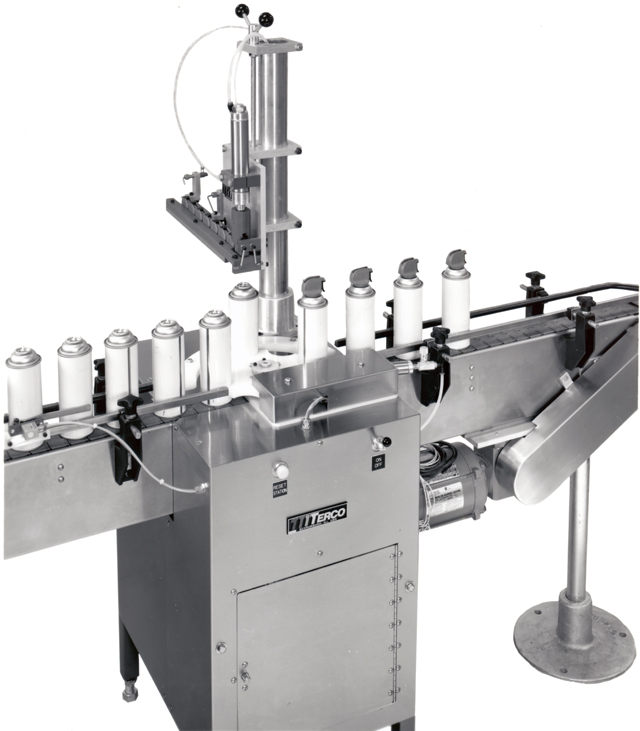

Aerosol Can Filler Machines: How They are Made, What’s It’s Utilized For, and Why Terco Makes the Best Machines

Aerosol cans are a common strategy to provide a wide run of items – from life-saving inhalers to antiperspirants. However, have you ever considered how these machines are made to fill these pressurized containers? Aerosol can filler machines are engineering and manufacturing marvels that hold the key to the solution.

Other Articles You Might Be Interested In:

- What is Bag-On-Valve (BOV) Aerosol Filling?

- Product: Rotary Indexing Machines

- How To Choose Aerosol Filling Companies?

Engineering and Manufacturing Aerosol Can Filler Machines

Precision engineering is at the heart of an aerosol can filler machine. These machines meticulously handle various product phases – liquids, propellants, and gases – ensuring they are dispensed into the can in the correct sequence and proportions.

Here’s a glimpse into the key components and processes involved:

- Filling Stations:

These stations accurately measure and inject the product formula, typically a liquid concentrate. - Propellant Stations:

Liquefied propellants are precisely filled to create pressure within the can and expel the product. - Valving Systems:

Sophisticated valves control the flow of product and propellant at each stage, ensuring a clean and measured filling process. - Seaming and Creasing:

To halt spills and protect weight, the can is hermetically fixed after it has been filled employing a seaming or creasing component. - Highlights for Security:

Airborne can filler machines have security highlights like explosion-proof walled in areas and fire concealment frameworks since forces are combustible materials.

Capability in numerous building disciplines is vital for the generation of these machines. The filling instruments and center structure are outlined by mechanical engineers. Chemical engineers make beyond any doubt that the materials utilized within the machine and the merchandise being filled are consistent. To guarantee secure operation, computerization is coordinates by electrical and control engineers.

Diverse Applications of Aerosol Can Filler Machines

The flexibility of airborne can filler machines expands to a wide extend of applications over different businesses:

Personal Care Items:

From hairspray and antiperspirants to shaving creams and sunscreens, these machines fill the holders that keep us looking and feeling our best.

Household Items:

Discuss fresheners, creepy crawly repellents, and cleaning splashes all depend on airborne can fillers for steady and pressurized apportioning.

Nourishment and Refreshment Items:

Whipped cream canisters and spray-on cooking oils are effectively filled utilizing these machines.

Pharmaceuticals:

Metered-dose inhalers for asthma and other respiratory conditions require exact filling with pharmaceutical and fuels, a errand dealt with by specialized vaporized can fillers.

Industrial Applications:

From oils and degreasers to paints and coatings, airborne can fillers play a imperative part in different mechanical segments.

Why Terco Should Be Your Choice for Aerosol Can Filler Machines

When it comes to choosing a producer for your vaporized can filler machine, a few variables come into play. Here’s why Terco ought to be your best thought:

Involvement and Mastery:

With a long time of involvement in planning and building aerosol can fillers, Terco offers a demonstrated track record of quality and unwavering quality.

Customizable Arrangements:

Terco gets it that each machine and generation line has special needs. They give customizable arrangements to coordinate your particular filling prerequisites, guaranteeing ideal effectiveness.

Security Center:

Terco prioritizes cutting-edge security highlights in their machines, ensuring a secure working environment for your administrators.

After-Sales Support:

A solid after-sales support is vital for keeping your machine working. Terco offers comprehensive support to keep your operation running easily.

By investing in a high-quality Terco aerosol can filler machine, you pick up a reliable long-term partner. Their commitment to advancement, security, and client fulfillment makes them the perfect choice for businesses looking to fill aerosol cans productively and dependably.

Terco’s Aerosol Filling Equipment: Elevate Your Production with Our Cutting-Edge Aerosol Filling Equipment Solutions

With a rich heritage spanning over five decades, our company specializes in the engineering and manufacturing of Terco’s aerosol filling equipment, catering to diverse applications. Our global footprint boasts the successful installation of over 2,500 aerosol machines, establishing our reputation for delivering high-quality equipment within remarkably short lead times.

Our machinery portfolio encompasses a spectrum of options, ranging from low to high-speed equipment designed for aerosol and rotary liquid fill systems, rotary base crimpers, gasser/shakers, propellant and liquid fillers, and bag-on-valve (BOV) systems, among others.

Catering to a diverse array of market segments, including health and beauty, coatings and sealants, food, and chemical manufacturing, our equipment has become the trusted choice for manufacturers worldwide. Clients confidently rely on our solutions, knowing they seamlessly integrate into their operations, delivering exceptional performance tailored to their specific requirements.

Beyond our cutting-edge machinery, our aerosol team possesses extensive production line knowledge to address upstream and downstream challenges. Our engineers boast expertise in both mechanical and pneumatic aerosol technology, and our portfolio proudly features renowned brands such as Electromatic, LinearPak, UltraFlex, and FlexiPak.

Regardless of the application’s demands, our seasoned engineering team stands ready to provide tailored solutions. Our commitment is to be an operational asset for our clients, addressing challenges, fostering strong relationships, and delivering highly capable machinery precisely aligned with our clients’ needs.

Explore our comprehensive portfolio of aerosol filling equipment by clicking the link provided or scrolling down to discover the types of equipment we have successfully worked with.

Having served over 1,000 customers globally, we bring a wealth of collective confidence to all aerosol projects, irrespective of scope. Whether you require aerosol packaging equipment for your health and beauty products, coatings, sealants, food items, or chemicals, our experienced team is ready to assist. Submit your request, and our expert will promptly contact you to identify the ideal equipment for your production facility.

Contact Us to Elevate Your Production With Terco’s Cutting-Edge Aerosol Filling Equipment Solutions

Streamlining Production With Aerosol Filling Machines

Aerosol filling machines have transformed packaging across industries like personal care, pharma, and household goods. These machines stand out for their ability to preserve products, using pressurized containers to shield sensitive formulations from air and contaminants. This helps extend shelf life and maintain product quality.

For products like deodorants, hairsprays, and cleaners, where exposure to the environment can reduce effectiveness, this preservation is key. The precision of aerosol filling ensures each container is filled consistently, meeting consumer expectations and regulatory requirements. Plus, these machines support sustainability. Modern designs minimize waste by optimizing product use and cutting down on excess packaging—reducing costs while catering to eco-conscious consumers.

Technology has also evolved, allowing aerosol machines to handle a range of container shapes and sizes. This flexibility means manufacturers can expand their product lines without heavy investments in new equipment.

Aerosol filling machines are a powerhouse for companies that want to push the envelope while staying lean and mean. With their unmatched versatility, they’re the secret weapon for outpacing the competition in today’s high-speed market.

Main Points

- Aerosol filling machines turbocharge production, ramping up speed and precision for a leap in efficiency and major cost savings.

- Automation takes the wheel, slashing manual labor and eradicating human error for flawless results every time.

- When picking the right aerosol filler, don’t overlook key factors like production capacity, container sizes, and the thickness of your product—it’s all about the perfect match.

- Integrating aerosol machines into existing lines? It’s all about strategy—plan it right, and you’ve got a seamless, high-performing operation in no time.

- Quality and safety are locked in with regular maintenance, top-notch training, and strict adherence to industry standards—because in aerosol filling, there’s no room for compromise.

How Aerosol Filling Machines Boost Efficiency

Aerosol filling machines have revolutionized manufacturing, turbocharging production speeds and slashing time-to-market. These high-speed powerhouses replace tedious manual labor, filling and sealing products faster while ensuring top-notch quality.

Speed Meets Precision

With the ability to fill thousands of cans per hour, aerosol machines keep pace with high-demand industries where speed is everything. Automation slashes human error, delivering precise, consistent fills with every can. This isn’t just fast—it’s flawless, driving customer satisfaction and quality control.

Smarter Manufacturing with Tech

Today’s aerosol machines come with advanced software that tracks real-time data, giving manufacturers instant insights into production. Monitoring key metrics helps pinpoint bottlenecks, streamline workflows, and minimize downtime—leading to smarter decisions and smoother operations.

Flexibility for Fast-Paced Markets

Aerosol filling machines are adaptable, switching between product lines or formulations on the fly without major reconfigurations. This flexibility is a game-changer in a fast-evolving market, helping companies pivot quickly and stay ahead of consumer trends.

The Power of Automation in Aerosol Filling

Automation is the game-changer in aerosol filling, driving precision and consistency that manual labor can’t match. With sensors and controls tracking pressure, temperature, and fill volume, automated machines adjust in real-time to ensure every can meets high-quality standards. This leads to reliable production, fewer defects, and reduced risk of costly recalls.

Beyond quality, automation slashes labor costs and minimizes workplace injuries tied to heavy or hazardous materials. Fewer workers are needed on the line, so companies can focus human resources on skilled tasks or creative input. Plus, automated systems run around the clock with minimal supervision, boosting output and cutting downtime—more cans, less hassle.

Choosing the Right Aerosol Filling Machine

Selecting the right aerosol filling machine is crucial for optimizing production. The product’s formulation plays a big role—thicker liquids or propellant-based products require specialized equipment. Container size and shape matter too. Machines that can handle different types of packaging offer more flexibility in a fast-changing market.

Another key decision is automation level. Fully automated systems deliver peak efficiency but come with a higher price tag and complex maintenance. Semi-automated or manual machines are more budget-friendly but might limit scalability. Companies must also ensure their new equipment integrates smoothly with existing production lines.

Doing the research and consulting experts can help manufacturers make smart choices that align with both their immediate needs and future growth.

Considerations for Choosing the Right Aerosol Filling Machine

| Consideration | Description |

|---|---|

| Production Capacity | The number of aerosol cans the machine can fill per hour or day. |

| Aerosol Can Size Range | The range of can sizes the machine can accommodate for filling. |

| Filling Accuracy | The precision and consistency of the filling process to ensure accurate product volume in each can. |

| Product Compatibility | The types of products (e.g. liquids, gels, creams) that the machine can fill without causing contamination or clogging. |

| Automation Level | Whether the machine is manual, semi-automatic, or fully automatic in its operation. |

| Footprint and Space Requirements | The physical dimensions and space needed for installing the machine in the production facility. |

| Cost and Return on Investment | The initial cost of the machine and the potential return on investment based on production efficiency and product quality. |

Choosing the Right Aerosol Filling Machine

Selecting the right aerosol filling machine is a game-changer for a company’s success. First, consider the product—viscosities and propellants call for specialized equipment. The machine needs to match your product’s unique needs, whether that’s thick creams or gas-powered sprays.

Container size and shape matter too. A flexible machine that adapts to different container types will keep you agile in a fast-evolving market. And let’s not forget automation: fully automated systems boost efficiency and consistency, but come at a higher upfront cost and demand more maintenance. For smaller operations, semi-automated or manual systems might be more cost-effective but could limit scalability.

Lastly, make sure the machine meshes well with your current setup—seamless integration is key. Do your homework, consult experts, and choose a machine that aligns with your goals for both the present and future.

Integrating Aerosol Filling Machines into Production Lines

Integrating aerosol filling machines into your existing production line is both a challenge and an opportunity. The main hurdle? Making sure the new machinery clicks with your current equipment and workflow. You may need to tweak conveyor systems, adjust layouts, or implement new software to optimize performance.

But when done right, the payoff is huge. A well-executed integration can streamline operations, reduce waste, and supercharge production efficiency. Strategic placement of the machines can cut down handling times, while connecting them to automated systems like labeling and packaging boosts throughput and slashes labor costs.

Training your team on the new tech is also crucial—skilled employees are more engaged and adaptable, helping the entire production process stay nimble and responsive to changes.

Quality and Safety in Aerosol Filling

In aerosol filling, safety and quality aren’t optional—they’re essential. With pressurized products, even a small slip-up can lead to major recalls. That’s why rock-solid quality control is a must: regular calibrations, constant inspections, and rigorous product testing ensure every can is spot-on.

Safety’s just as crucial. Many aerosols contain flammable or toxic substances, so airtight handling protocols are key—think ventilation, PPE, and thorough safety training. Staying up-to-date with industry standards like OSHA and EPA isn’t just about compliance; it’s about creating a safe, sustainable workplace where products shine and employees thrive.

Exploring Bag-on-Valve Dispensing Systems

Ready to elevate your aerosol game? The Bag-on-Valve Dispensing System could be your secret weapon. With its unique dispensing power, it’s perfect for specific aerosol products. Want to know how it works and why it could be a perfect fit? Dive into our full guide on Bag-on-Valve Dispensing Systems for all the details and benefits.

Contact Us for more information about our Aerosol Filling Machines

The Bag-On-Valve Aerosol System: A Packaging Marvel

In our ever-evolving world, packaging technology continues to push boundaries. One remarkable solution leading the way is the Bag-On-Valve (B.O.V.) aerosol system. Created for liquid and viscous products, this ingenious system has become a packaging game-changer. In this article, we’ll dive into the B.O.V.’s inner workings and explore its numerous advantages and applications across industries.

How the Bag-On-Valve Aerosol Works

The B.O.V. system’s concept is elegantly simple. It ensures a complete separation between the product and the propellant, usually eco-friendly air or nitrogen. This separation guarantees the product remains uncontaminated, maintaining its quality throughout its shelf life.

This system is typically housed in aluminum cans with a one-inch opening where the valve is securely crimped. The valve connects to a foil-based packaging bag with a multi-layer film laminate. Once the valve is crimped in place, compressed air or nitrogen is introduced between the bag and the can. This process, known as “under the cup gassing,” ensures the product and propellant stay separate, preserving their distinct identities within the package.

Advantages of the Bag-On-Valve System

The Bag-On-Valve aerosol system offers a multitude of benefits that make it a packaging frontrunner. Here are some key advantages:

- Superb Barrier: The four-layer laminate bag provides an exceptional barrier, preventing oxidation and safeguarding products prone to degradation.

- Complete Product Isolation: Products are hermetically sealed within the bag, guaranteeing their integrity remains intact.

- Safety: B.O.V. systems utilize non-flammable propellants, eliminating the risk of explosions or gas-related hazards.

- Hygiene and Sterilization: Its design allows for easy sterilization, making it ideal for pharmaceutical and personal hygiene items.

- Efficiency: Up to 99.5% of the product can be dispensed, reducing waste and maximizing utility.

- Versatility: B.O.V. systems dispense products from any angle with 360° actuation, offering controlled spray patterns for optimal results.

- User-Friendly: Unlike traditional aerosols, B.O.V. systems require no pumping motion, making them convenient and efficient.

- Environmentally Friendly: Hailed as the “GREEN” alternative to standard aerosols, this system is eco-friendly and 100% recyclable.

- Wide Range of Applications: The B.O.V. system accommodates various product types, from cosmetics to food, pharmaceuticals to household products, and can be used with standard actuators and aerosol cans.

Applications of the Bag-On-Valve Aerosol System

The B.O.V. system’s versatility shines through its diverse applications. If a product’s viscosity allows passage through the valve stem, it can find a home within this innovative packaging solution. Some noteworthy applications include:

Cosmetics:

- Sunscreen (SPF’s)

- Lotions

- Creams

- Facial Cleansers

- Self-Tanners

- Personal Hygiene Items

Pharmaceutical & OTC:

- Wound Washes

- Nasal Sprays

- Ear Washes

- Eye Washes

- First Aid Sprays

- Baby Care Products

Food:

- Cooking Oils

- Liquid Flavorings

- Vinegar

- Salad Dressings

- Ketchup

- Mustard

- Jellies

- Coffee/Tea Concentrates (with pending patents)

Miscellaneous:

- Liquid Fire Extinguishers

- Air Fresheners

- Odor Eliminators

- Car Care Products

- Hunting Products

- Disinfectants

- Furniture Polish & Cleaners

In conclusion, the Bag-On-Valve aerosol system is a packaging marvel that has transformed industries.

Bag-On-Valve Manufacturing

Terco manufactures the most reliable bag-on-valve machines in the world. With over 50 years of supplying the highest quality machinery, we have developed an experience base unmatched by others. To this we add our extensive engineering and manufacturing capabilities to allow a system to be configured that meets the exact needs of your application. Systems that are fully capable of meeting the needs of today and tomorrow.

How Does Bag-On-Valve Work?

Bag-on-Valve (BoV) technology is a form of aerosol packaging used in a variety of industries, ranging from food and beverages to cosmetics and medical supplies. The technology involves a flexible container that houses the product, with an airtight valve attached to the container. When the valve is pressed, a spray or foam is released from the container. The process works by creating a pressure difference inside and outside of the container.

When the valve is pressed, air is forced from outside of the container into the bag. This increase in pressure forces the product out of the container, creating a fine spray or foam. The advantage of this system is that it does not require any additional pressurization or propellants. This makes it a safe, economical and environmental friendly way to store and dispense products.

Overall, Bag-on-Valve technology is an efficient and safe way to package and dispense a variety of products. It provides an easy to use, cost-effective solution with no additional pressurization or propellants required. It is also highly environmental friendly, as it does not involve any hazardous chemicals or gases.

Contact Terco – The Bag-On-Valve Manufacturing Company

Bag On Valve Dispensing System

Bag on valve (BOV) aerosol filling is a packaging technology that has gained popularity over the years due to its unique benefits. It is a type of aerosol packaging that consists of a bag, which acts as the product container, and a valve, which acts as the dispenser. This technology offers several advantages over traditional aerosol packaging methods, making it a preferred choice for many products.

The BOV aerosol filling process begins by filling the bag with the product. The bag is then placed inside the aerosol can and sealed. The valve is then attached to the can, creating a seal between the bag and the valve. The valve is designed to dispense the product from the bag when it is pressed, allowing the product to be released in a controlled manner.

One of the main advantages of BOV aerosol filling is that it eliminates the need for propellants. Traditional aerosol packaging methods require the use of propellants, which can be harmful to the environment and health. BOV aerosol filling technology allows for products to be dispensed using air pressure, which is much safer and more environmentally friendly.

Another benefit of BOV aerosol filling is that it allows for products to be dispensed in any position. Traditional aerosol packaging methods require the can to be held in a specific position to dispense the product. BOV aerosol filling allows for the product to be dispensed in any position, making it easier to use and more convenient.

BOV aerosol filling technology is also ideal for products that are sensitive to air or moisture. The bag acts as a barrier, protecting the product from air and moisture, which can affect the product’s quality and efficacy. This makes it a suitable choice for products such as pharmaceuticals, cosmetics, and food products.

In addition, BOV aerosol filling technology allows for products to be dispensed more efficiently. The bag can be completely emptied, reducing product waste and increasing product yield. This is particularly important for high-value products, where even small amounts of waste can have a significant impact on profitability.

BOV aerosol filling technology has gained widespread acceptance in a variety of industries, including pharmaceuticals, cosmetics, and food products. Its unique benefits have made it a preferred choice for many manufacturers, who are seeking to enhance their product offerings while reducing their environmental impact.

In conclusion, BOV aerosol filling technology offers a range of benefits over traditional aerosol packaging methods. Its ability to eliminate the need for propellants, dispense products in any position, protect products from air and moisture, and increase product yield has made it a popular choice for many manufacturers. As technology continues to evolve, it is likely that we will see further innovations in this area, further enhancing the benefits of BOV aerosol filling technology.

Related Articles

WHAT IS BAG-ON-VALVE AEROSOL FILLING?

Bag-on-valve aerosol filling is the process of filling a flexible bag with a liquid or semi-liquid product and then sealing it inside a metal aerosol can along with a propellant. The bag is separated from the propellant by a valve, which controls the dispensing of the product.

The process typically involves several steps:

- The flexible bag is placed inside the metal can and the valve is attached to the top of the can.

- The product is then filled into the bag through a filling nozzle.

- The bag is then sealed and the can is filled with the propellant.

- The valve is then crimped onto the can to create an airtight seal.

The filling process is typically done using specialized equipment and automation to ensure accurate filling and consistent quality.

Once the can is filled, it is ready for dispensing. When the valve is actuated, the propellant pushes the product out of the bag and through the valve, dispensing it into the air as a fine mist or spray.

BOV aerosol filling technology is a versatile solution that can be used in a wide range of industries, including personal care, food and pharmaceuticals. Due to its consistent and controlled dispensing, it is ideal for products that require precise application, such as hair sprays, insect repellents and cooking oils.

Efficient Aerosol Filling Machines for Streamlined Production

Efficient Aerosol Filling Machines for Streamlined Production

Specialized machinery known as aerosol filling machines is used to fill containers with aerosol products, which are usually pressurized and sprayed or misted finely. Numerous industries, such as the food and beverage, pharmaceutical, household goods, and personal care sectors, depend heavily on these machines. Due to the need for accuracy, efficiency, & adherence to strict safety regulations, aerosol filling technology has undergone significant development over time. Manufacturers are spending more money on cutting-edge filling technologies to increase production capacity as consumer demand for aerosol products keeps growing.

Key Takeaways

- Aerosol filling machines are used to fill aerosol products such as spray paints, deodorants, and air fresheners into cans or bottles.

- Key features of efficient aerosol filling machines include high filling accuracy, quick changeover between products, and minimal product wastage.

- Using efficient aerosol filling machines can lead to increased productivity, reduced production costs, and improved product quality.

- When choosing an aerosol filling machine, factors to consider include production capacity, filling accuracy, ease of maintenance, and compatibility with different aerosol products.

- Case studies have shown successful implementation of efficient aerosol filling machines leading to improved production efficiency and cost savings for companies.

- Future trends in aerosol filling machine technology include advancements in automation, integration of smart technology for real-time monitoring, and development of eco-friendly filling solutions.

A number of crucial procedures are involved in the aerosol filling process, such as product preparation, propellant and product filling, container sealing, & quality control standards compliance. Because of its intricacy, this process requires the use of advanced equipment that can work with a wide range of products, including liquids, powders, gels, and foams. Manufacturers hoping to maximize production lines and successfully satisfy consumer demands must comprehend the complexities of aerosol filling machines. A number of essential characteristics that improve their dependability and performance define efficient aerosol filling machines. The automation feature is among the most important ones. In order to reduce the need for manual intervention, modern machines frequently integrate automated systems that streamline the filling process.

By reducing human error and speeding up production, this automation guarantees consistent quality throughout batches. Fully automated systems, for example, can manage several filling stations at once, enabling increased throughput without sacrificing accuracy. The capability to manage different container sizes and shapes is another essential feature. Effective aerosol filling machines are made with movable parts that can hold a variety of cans and bottles, from tiny personal care items to bigger industrial uses. For producers of a wide variety of goods, this adaptability is crucial.

Also, many machines have sophisticated sensors and monitoring systems that give operators real-time information on pressure, filling levels, and other parameters. This information helps operators make well-informed decisions and adjustments throughout production. Using effective aerosol filling equipment has several advantages for producers. Enhanced productivity is one of the main benefits.

| Machine Type | Production Capacity | Filling Accuracy | Operational Speed |

|---|---|---|---|

| Automatic Aerosol Filling Machine | Up to 60 cans per minute | ±0.5% of filling volume | Adjustable, up to 100 cans per minute |

| Semi-Automatic Aerosol Filling Machine | Up to 30 cans per minute | ±1% of filling volume | Adjustable, up to 60 cans per minute |

Manufacturers can greatly cut cycle times and boost output by automating the filling process and improving machine performance. This is especially crucial in sectors where demand varies quickly because it enables businesses to react swiftly to shifts in the market without compromising quality. Also, effective aerosol filling equipment eventually results in cost savings.

Even though purchasing sophisticated machinery may require a large initial outlay, over time, the savings in labor expenses, waste, and product rework can result in sizable financial gains. For instance, automated systems frequently require fewer operators than manual filling lines, enabling businesses to more efficiently allocate their workforce. Precise filling also lessens the possibility of overfilling or underfilling containers, which minimizes product loss & guarantees regulatory compliance. In order to make sure that an aerosol filling machine fits the unique requirements of a manufacturing operation, a number of factors need to be considered. The kind of product being filled is one of the most important factors to consider.

Certain products have special qualities that call for particular handling methods. For example, a different filling mechanism might be required for viscous liquids as opposed to lighter sprays or foams. Comprehending the product’s attributes will assist manufacturers in selecting a machine that can provide the best possible performance. Production capacity is another important consideration. When choosing a machine, manufacturers need to consider both their present and future production volumes in order to avoid bottlenecks.

In addition to the machine’s speed, this entails assessing how well it can manage several product lines or variations. It is also important to take into account the production facility’s space limitations, as certain machines may need more floor space than others because of their configuration or design. Effective aerosol filling machines have been successfully installed by a number of businesses, increasing output & improving product quality. One prominent example is a well-known personal care company that encountered difficulties with its manual filling procedure. The business made the decision to purchase a fully automated aerosol filling line that could process several product formulations at once. They were able to maintain strict quality control procedures while experiencing a 50% increase in production speed as a result.

Also, the new system made it possible to monitor filling parameters in real time, allowing for prompt adjustments that further improved performance. The food industry provides another example, where a cooking spray manufacturer aimed to increase production efficiency. The company was able to cut its cycle time by 30% by switching to a high-speed aerosol filling machine with cutting-edge propellant integration technology. Along with improving output, this upgrade also decreased waste during the filling process & improved product consistency. By successfully implementing this technology, the manufacturer was able to increase the range of products it offered while upholding strict safety and quality standards. Innovation and shifting consumer needs are expected to propel major advancements in aerosol filling machine technology in the future.

Incorporating Industry 4.0 principles into aerosol filling operations is one new trend. Using IoT (Internet of Things) devices to collect and analyze data in real time during the production process is one example of this. Manufacturers can improve maintenance schedules, pinpoint possible problems before they become serious, and obtain insights into machine performance by utilizing data analytics. Also, aerosol filling technology is increasingly focusing on sustainability. Manufacturers are looking for ways to cut waste & their carbon footprint as environmental concerns increase.

This has prompted the creation of recyclable packaging materials and environmentally friendly propellants that satisfy consumer demands for sustainable goods. Features like systems made for simple cleaning & maintenance or those that make use of energy-efficient technologies may be incorporated into future aerosol filling machines to support these sustainable practices. In conclusion, aerosol filling machines are essential to many sectors of the economy where accuracy and efficiency are critical. In order to stay competitive in a market that is constantly changing, manufacturers need to keep up with the latest developments in machinery design and functionality.

FAQs

What is an aerosol filling machine?

An aerosol filling machine is a specialized piece of equipment used to fill aerosol cans with various products such as paints, lubricants, foams, and other pressurized substances.

How does an aerosol filling machine work?

Aerosol filling machines typically work by first pressurizing the can with propellant, then filling it with the desired product, and finally sealing the can with a valve and actuator.

What are the different types of aerosol filling machines?

There are various types of aerosol filling machines, including semi-automatic machines, fully automatic machines, and rotary indexing machines, each with different levels of automation and production capacity.

What are the benefits of using an aerosol filling machine?

Using an aerosol filling machine can increase production efficiency, ensure accurate filling and sealing, reduce product waste, and improve overall product quality and consistency.

What industries use aerosol filling machines?

Aerosol filling machines are used in a wide range of industries, including automotive, household products, personal care, pharmaceuticals, and industrial applications.

Bag On Valve Aerosol

Bag On Valve BOV aerosol technology is a new way of packing your products. Are you looking for a packaging solution for your aerosol products? Such as cosmetic and beauty products, food products, pharmaceutical products, fire extinguisher etc. Or you just tired of using traditional aerosol packaging technology? Then why not try to use bag on valve aerosol technology to fix your packing issues?

Conventional aerosol spray technology

Conventional aerosol packaging combines three elements:

- Product to be sprayed: blending active and inactive ingredients.

- Propellant: a gaseous compound mixed with the product to ‘push’ it out as spray or foam. In some cases, the propellant also acts as a solvent to keep the product in desired form. Usually, the propellants is a naturally occurring hydrocarbon, like propane, isobutane, normal butane or ethane, or a hydrofluorocarbon like HFC 134 or HFC 152.

- Canister: steel or aluminum leak-proof can, fitted with push-button spray valve, to keep product/propellant mix contained under pressure,

- Pressing the actuator button opens the valve. Differential pressure between can contents and outside atmosphere allows propellant to expand, pushing the product out through the valve as fine mist or jet spray.

Bag On Valve aerosol technology

The Bag on Valve aerosol system is built around an aerosol spray valve welded to a sealed poly-laminated aluminum bag. When filled with product, the bag is placed inside a tinplate or aluminum can that is then pressurized with compressed air or nitrogen propellant as valve is fitted under pressure.

In use, the propellant exerts pressure on the outside of the bag, ‘squeezing’ product through nozzle in a mist or jet spray when the valve is actuated.

There are three key differences between a standard aerosol and BoV spray delivery:

- Product and propellant remain physically separate eliminating the risk of adulteration or contamination

- Less aggressive propellants can be used

- The product undergoes less chilling from the propellant and emerges closer to room temperature.

Why Bag on Valve Aerosol Spray?

- Better Quality Of Finished Aerosol Products.

The finished aerosol product with bag on valve technology has better spray effect, mainly reflected in the wider spray range, the spray molecular weight is more even and finer, and it is easier to be absorbed.

- No Limited Substances.

The gas and the material in the traditional aerosol spray technology must be mixed, so the choice of the substances is limited.

The gas and substances in the bag on valve packaging technology are separated, there would be no limit for the used material.

- Safety Guarantee.

The most commonly used gas in traditional aerosol spray packaging is propane, which is very easy to explosive in high temperature or high pressure environment.

Therefore, the traditional aerosol spray packing can not be taken on the plane. The gas in the bag on valve package is usually nitrogen or compressed air, these kind of gases are safe.

- More Environmentally Friendly.

The gas and material of the bag on valve package are separated. The material is filled into an vacuum bag, but the compressed air is filled between the bag and the cans.

The compressed air squeeze the bag to spray the material, thereby avoiding pollution caused by direct contact.

The whole filling process are finished in the aseptic workshop, and the whole process guarantees aseptic operation.