Bag on Valve Aerosol Filling Machines

Bag on Valve (BoV) technology has revolutionized the aerosol packaging industry. This ground-breaking technology changed product packaging by fusing sustainability and convenience.

But what makes BoV unique? Picture your product securely enclosed in a pliable bag that is fastened shut with an advanced valve. This clever filling method ensures that your products reach customers in perfect condition by improving product protection and extending shelf life.

BoV has a striking effect on manufacturers. Modern bag on valve filling machines allow businesses to package a wide range of products, from pharmaceutical wonders to personal care wonders, with ease.

Still, that’s not all! Businesses that embrace the bag on valve filling machine also embrace sustainability, which is important to today’s consumers. By partnering with environmentally friendly packaging options, your business attracts customers and makes a splash in a market that is eager to buy green products.

Join the leaders in the industry and make a splash with this alluring, innovative, and ecologically beneficial method by embracing the future of aerosol filling. The bag on valve filling process has revolutionized aerosol packaging.

Advantages of Bag on Valve Packaging

- Bag on Valve (BoV) packaging provides maximum product protection with an extended shelf life. Manufacturers looking to preserve the quality of their products finds this technology advantageous.

- BoV technology is an eco-friendly option. It has a significantly smaller environmental impact than traditional aerosol packaging, demonstrating a commitment to environmental responsibility.

- The valve filling machine’s bag ensures accurate product dispensing, making controlled dispensing simple and reliable. This improves user experience and lowers product waste.

- BoV is a versatile packaging solution. It is used in a wide range of consumer products, including food, pharmaceuticals, personal care and household items.

- The bag on valve aerosol filling machine packaging conforms to strict regulations and safety standards. It ensures consumer safety and product integrity. Manufacturers are adopting the bag on valve filling machine due to its efficacy.

- Modern bag on valve aerosol filling equipment can help businesses improve productivity, expedite the manufacturing process, and meet customer expectations more rapidly.

- Producers can improve product performance and quality with the bag-on valve filling machine, which will increase customer satisfaction and brand loyalty.

- The sophisticated technology of the valve filling machine’s bag guarantees accurate and airtight valve crimping, which is essential for preserving product freshness and averting leaks.

- BoV packaging is a packaging method that give consumers’ growing demand for sustainable and eco-friendly packaging options.

- Manufacturers using bag on valve packaging obtain a competitive advantage in a fiercely competitive market by providing innovative, aesthetically pleasing, and eco-friendly solutions.

- The bag on valve filling machine revolutionizes packaging and offers producers and consumers a number of environmentally friendly advantages. It is popular for a range of products due to its extended shelf life, reduced environmental impact, precise dosage, and regulatory compliance.

- Manufacturers may embrace sustainability and technical improvements while preserving product quality and successfully satisfying client demands by investing in the bag on valve aerosol filling machine.

Innovative Packaging Solution: The Bag on Valve Aerosol Filling Machine

The bag on valve aerosol filling machine is a revolutionary method for packaging products with propellant, creating airtight seals between the product pouch and aerosol valve. This unique system allows for clean, hygienic, and leak-free dispensing.

Parts and Operational Concept Of BoV Machines

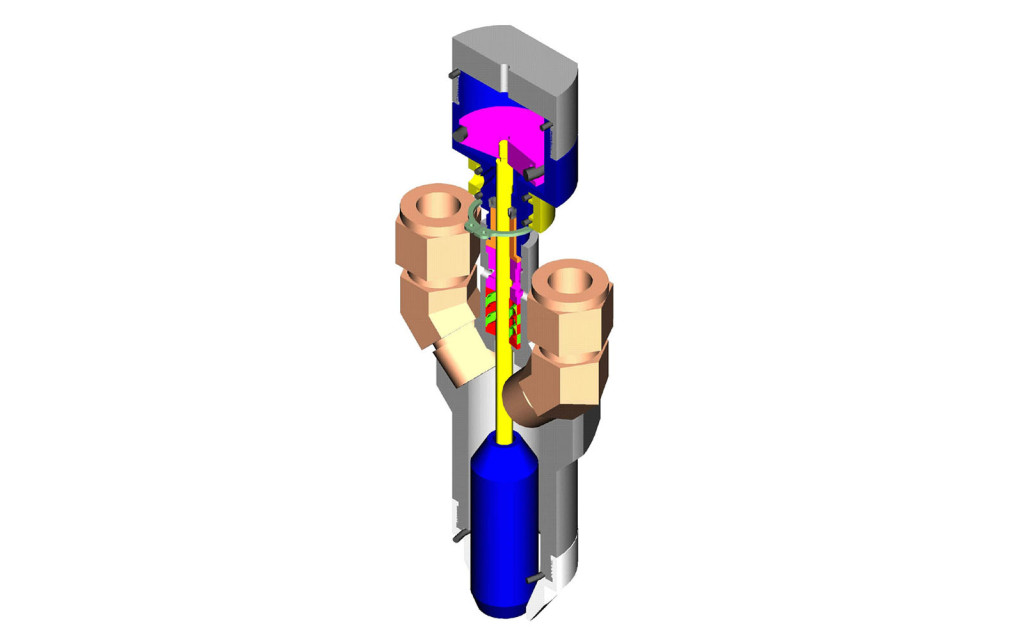

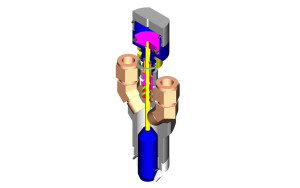

The product reservoir, the propellant gas chamber, the valve crimping system, and the nozzle are some of the key parts of the bag-on-valve aerosol filling machine.

These devices operate on the basis of the product being placed inside a flexible bag and sealing it hermetically. The bag is enclosed in a rigid aerosol can with a valve attached to the top.

Strict safety and quality requirements are met by the bag on the valve filling machine.

Types of Bag on Valve Aerosol Filling Machines

There are three types of bag on valve aerosol filling machines to choose from, depending on your production scale and requirements.

Manual filling machines, ideal for small-scale production, involve manual loading and sealing of bags.

Semi-automatic filling machines are suitable for medium-sized production lines, automating some processes while still requiring human operators for specific tasks.

Fully automatic filling machines are designed for high-volume production, fully automating the entire filling process from bag insertion to valve crimping.

Choose Efficiency and Quality with the Bag on Valve Aerosol Filling Machine

Armed with this information, select the perfect bag on valve aerosol filling machine for your specific needs and ensure top-notch packaging for your valuable product. Let this innovative technology take your packaging to the next level.

Suppliers of the Bag on Valve Filling Machine

Several distinguished manufacturers offer cutting-edge bag-on valve-filling machines with advanced technology and innovative features. Some notable suppliers include Terco, Inc. renowned for their dependable and efficient systems.

Manufacturers can gain a competitive edge by offering products with better user experiences, longer shelf lives, and environmentally friendly packaging with the bag on valve aerosol filling machine.

Adopting this innovative technology creates new opportunities for a variety of industries, including pharmaceuticals and cosmetics, as it ensures optimal product protection and precise, controlled dispensing. Choosing an automatic, semi-automated, or manual bag on valve filling machine is just one option for the bag on valve approach, which provides packaging solutions that are both customer-focused and sustainable.

The Bag on Valve Filling Process: A Step-by-Step Guide

When it comes to the bag on-valve filling procedure, product preparation, gas selection, and filling all play important roles. These crucial elements are key to ensuring the precise and effective packaging of various items using a sophisticated bag on valve aerosol-filling machine.

Step 1: Product Preparation

First, a specially designed laminated bag is filled with the desired goods, serving as the primary container for the product.

Step 2: Hermetic Sealing

Next, the bag is hermetically sealed to prevent any interaction between the product and the propellant or outside environment.

Step 3: Assembly

The sealed bag is then placed inside the aerosol can, which serves as the secondary container. A dip tube-equipped aerosol valve is crimped onto the can to ensure a secure fit.

Step 4: Pressurization

Once assembled, an appropriate propellant is used to pressurize the aerosol can.

Step 5: Dispensing

When the customer depresses the actuator, the propellant forces the product through the dip tube and valve, effectively dispensing it from the bag.

Benefits of Bag on Valve Filling

Complete product evacuation is made possible by the bag on valve filling method, which reduces waste and maximizes utilization. The risk of contamination is removed by separating the product from the propellant, protecting the integrity of the product and prolonging its shelf life. Bag on valve technology’s adaptability also helps manufacturers by making it appropriate for a variety of uses, such as household goods, medications, and personal care products.

Gas Selection: A Crucial Step

The success of the bag on valve filling process relies heavily on the appropriate gas selection. Manufacturers carefully choose the gas based on product requirements, such as propellants for foaming products or inert gasses for sensitive formulations. The selected gas plays a crucial role in effectively dispensing the product and maintaining its integrity.

Valve Crimping and Sealing Techniques

Once the product and gas are combined, the next step is valve crimping. Its purpose is to securely attach the valve to the bag, preventing any potential leakage or contamination. To ensure consistency and efficiency in production, advanced bag on valve aerosol filling machines utilize automated crimping techniques. Additionally, proper sealing techniques are implemented to safeguard the product and maintain its shelf life.

Quality Control during Filling

Throughout the filling process, stringent quality checks are employed. Constant monitoring of weight and pressure measurements guarantees consistent product quantities and can integrity, ensuring that the final product meets safety standards.

The filling process entails placing the product in the bag and then positioning it inside the aerosol can. The crucial valve crimping step prevents any leakage, while the choice of propellant gas plays a significant role in the product’s performance.

Careful quality control measures are integrated throughout the entire process. Specialized equipment and machinery are utilized to ensure precise filling and to maintain the integrity of the finished product. The bag on valve filling machine presents manufacturers with various benefits, including improved user experience, increased shelf life, and environmental friendliness.

For businesses seeking to be environmentally and consumer-friendly, the bag on valve filling machine offers a robust alternative to conventional aerosol packaging. This cutting-edge technology has widespread application in multiple sectors, from personal care to medicine and home goods. Embracing this technology can help companies achieve a more eco-friendly and productive future.

Innovative Uses of Bag on Valve Technology

The bag on valve technology is being adopted by numerous industries, most notably the personal care and cosmetics sector. Manufacturers have recognized and implemented the benefits of using a bag-on-valve aerosol filling machine when packaging products like sunscreen and hair sprays. Customers are guaranteed a continuous and precise spray, enhanced product protection, and a reduction in contamination concerns with this cutting-edge technique.

The medical and pharmaceutical industries now acknowledge the advantages of bag-on-valve packaging. The bag hermetic seal of the valve aerosol filling machine extends the shelf life and preserves the sterility of the product, particularly for sensitive ingredients like wound washes, nasal sprays, and saline solutions. Increased reliability and safety are now advantages for products intended for patients and medical professionals.

In the food and beverage industry, bag on valve technology is quickly becoming a practical and hygienic packaging option. It is now possible to package items like whipping cream, cooking sprays, and oil mists using the bag on valve aerosol filling machine. This procedure ensures that the product’s quality and freshness are maintained while providing countless creative opportunities.

The home and business sectors have shown how versatile bag on valve technology is. In order to ensure controlled dispensing and minimize waste, cleaning agents, lubricants, and insect repellents are now packaged in bags on valve filling machines. The product’s effectiveness is maintained by the hermetically sealed bag, which prevents dangerous chemical reactions.

Thanks to the adoption of a bag on valve aerosol filling machine, manufacturers can now provide better products with a longer shelf life, a smaller environmental impact, and an improved user experience.

Bag on valve packaging has become a popular choice for businesses producing food, household goods, pharmaceuticals, personal care products, or other products that require innovative and sustainable packaging solutions.

Advantages for Manufacturers: Economical and Effective Production

The bag on valve filling machine offers a practical and economical way to package goods. Its efficient workflow lowers operating costs by minimizing production downtime and reducing material waste. These machines boost production efficiency, generating higher output while preserving product quality, with faster filling cycles and automated controls.

Market positioning and brand differentiation

By providing a distinctive packaging format, the bag on valve technology helps manufacturers stand out in a very competitive market. This creative aerosol packaging system gives products a perceived value boost, grabbing customers’ attention and offering fresh, practical solutions.

Consumer Preference and Demand for Sustainable Packaging

As consumers prioritize environmentally-friendly packaging, the bag on valve filling machine meets their needs by replacing toxic CFCs or hydrocarbon propellants with compressed air or nitrogen as propellants.

Using eco-friendly packaging makes a brand more palatable to consumers who care about the environment and strengthens its reputation for moral business conduct. Manufacturers can become industry leaders and gain a competitive edge by implementing bag on valve technology.

Comparison with Traditional Aerosol Packaging

BoV and Conventional Aerosols: A Comparative Analysis

Compared to conventional aerosol packaging, bag on valve filling machines use different technology. Propeller and product are kept apart in bag on valve systems until the product is distributed, preventing any possible chemical reactions and guaranteeing product integrity.

Conventional aerosols, on the other hand, combine the material and propellant, raising the possibility of chemical reactions and shortening the product’s shelf life.

Regulatory Aspects and Environmental Effects

Vacuum filling machines with bags on valves are a more environmentally friendly option. Strict environmental regulations are met by these cans since they don’t contain any hazardous CFCs or other ozone-depleting materials. Traditional aerosols, on the other hand, release propellants that are difficult to recycle and may be harmful to the environment.

Comparison of User Experience and Performance

Better performance and user experience are offered by the bag on valve aerosol filling machine. BoV technology ensures precise application and reduces waste by providing a consistent and controlled spray pattern. On the other hand, irregular spray patterns in conventional aerosols can result in inefficiencies and disgruntled customers.

Comparing the bag on valve filling machine to conventional aerosol packaging, there are a number of benefits. Propeller and product are kept apart to ensure longer shelf life and product integrity. It also offers an easy and effective spraying experience while adhering to current environmental regulations. It is therefore a very appealing option for businesses searching for a cutting-edge, eco-friendly packaging solution.

Bag on Valve Aerosol Cans Versus Traditional Aerosol Cans

You may have heard of the term “Bag on valve” aerosol cans and wondered to yourself what the difference is between this and traditional aerosol cans. Well, for starters, Bag on Valve aerosol cans, or BoV as it is commonly referred to, has a much longer shelf life than traditional aerosol cans. You don’t have to be an environmental enthusiast to realize that there are many ways that BOV aerosol cans are superior to their traditional predecessors.

BoV technology instantly separates propellants (nitrogen or compressed air) from the product by using flexible FDA-approved product filled laminated bags. These bags are placed inside of the aluminum or steel can and the propellant fills out the space between the bag and the can. Specialized BoV technology uses the energy of the propellant to push the product out of the bag when the actuator is pressed.

Product Emptying

Because of this technology, BoV aerosol cans are effortlessly able to provide consumers with product and makes product emptying a lot easier. In fact, BoV technology can provide up to 99-100% of product emptying! BoV aerosol cans are able to level up traditional cans in this category because BoV aerosol cans are able to separate the product from the propellant and use the propellant to squeeze the product out. Traditional aerosol cans do not have this feature. As a result, traditional cans generally run out of propellant before the entire product is used, meaning there is leftover, unattainable, wasted product!

BoV technology also uses the separation of product and propellant to protect the product from oxygen exposure with air-tight cans, because of this, products have an extended shelf life!

Types of Product

The advanced BoV technology has given various companies the freedom to place virtually any form of product in these cans. From gels to liquids, ointments, and creams BoV has made it possible to dispense many forms of product! Being able to place multiple forms of product in these cans can also increase brand recognition.

Having products placed into BoV aerosol cans makes life easier for the consumer. There are plenty of benefits that come with BoV technology like reduced spray noise, even dispensing at all angles (including the unheard of upside-down angle) and eliminates the need for pumping motion!

Non-Flammable & Environmentally Safe

Having non-flammable products is a great feature and you can bet your bottom dollar that Bov is non-flammable as well! What separates BoV aerosol cans apart from traditional aerosol cans in this category is that with traditional cans the propellants are mixed with the product, whereas BoV’s propellants are separated! The mixture of these two makes them flammable.

The use of, or in this case disposal of, non-flammable products makes getting rid of discarded cans safer and easier.

Another beautiful feature of BoV technologies is that these cans are sterile, hygienic and are generally free of preservatives. Because you don’t have to touch the product or even come in contact with it to dispense it ensures that these products are safe for the customer and pure in dispensing form.

So whether or not you’re a consumer or a manufacturer, BoV’s innovative technology continues to bring aerosol cans forward and have helped to bring overall consumer confidence and satisfaction back to aerosol cans!

LCN Series Dispensing Nozzle

LCN Series Dispensing Nozzle

Terco Announces LCN Series Filling Nozzle Development

Terco Announces LCN Series Filling Nozzle Development

Terco Inc., the Bloomingdale, IL (USA) manufacturer of aerosol and liquid filling equipment, announces the development of the Large Capacity Nozzles, otherwise known as the LCN Series. The nozzle series is an addition to the company’s current selection of dispensing nozzles.

The LCN Series was developed to handle products that are either foamy or of higher viscosities than can be easily handled by conventional filling nozzles. The units feature a larger dispensing orifice to increase the ratio of liquid cross section to atmosphere contact area, thus reducing the amount of agitation and air entrapment in the product stream. The nozzle is mounted to an articulated mounting that allows for adjustment to facilitate sidewall filling.

These improvements allow for faster filling times to increase line production speeds. Initial field production tests on aerosol glass cleaner products showed over a 40% reduction in the time required to liquid fill the product as compared with traditional filling nozzles.

In addition to being offered as upgrade options on all of the company’s standard products, the nozzles are designed for retrofitting to machines already in field service. This includes the advantage of being able to be fitted onto other manufacturers filling equipment.

According to the company “… the LCN Series nozzles represents our commitment to use the experience we have gained over the past 35 years to further improve the production output of the modern filling operation. Given the present economy and the increasing need for production line efficiencies, the nozzles offer a viable low cost solution to increasing the capacity of any filling operation.”

The LCN Series nozzles are constructed from either 300 Series or 316 Stainless Steel and feature anti-drip design. They also feature Terco’s dynamic seal technology that allows for adjustment of minor seal wear without the need to replace or rebuild the dispensing nozzle.

For further information:

Terco, Inc.

459 Camden Drive

Bloomingdale, IL 60108

USA

Phone: [+1] (630) 894 8828

Fax: [+1] (630) 894 8846

URL: www.terco.com

Contact: Bernie Brokke sales@terco.com

Bag-On-Valve Filling System

Bag-On-Valve Filling System

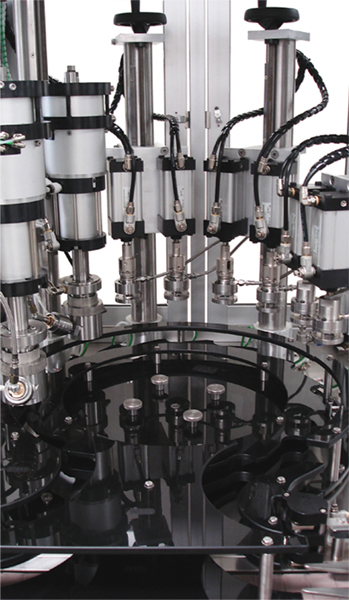

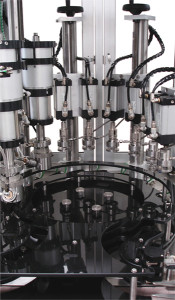

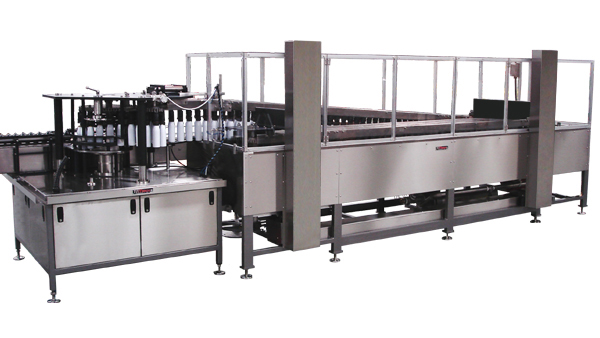

The BOV Rotary Indexing system is designed for use in the production of personal care products in bag-on-valve type containers. The system features the following production quality stations:

The BOV Rotary Indexing system is designed for use in the production of personal care products in bag-on-valve type containers. The system features the following production quality stations:

- Automated bag-valve insertion;

- Automated bag-valve placement verification;

- L.P.A.V. filling system to perform crimping and pre-charging of propellant on a single station. The unit is configured to handle liquefied and compressed gas propellants on the same station;

- HPTV High Pressure Product Fillers with sanitary construction;

- Automated Valve Stem Cleaner system to remove residual product after filling;

- And, online pressure testing for internal pressure verification.

According to the company, “… we have seen a number of applications in the past few years that involve the development of a barrier aerosol product. This product form is becoming increasingly popular by both producers and marketers who need specialized product delivery formats to both enhance their market positions and meet technical product specifications.”

In addition to the above filling system, the company will be displaying a range of aerosol filling stations used on various production systems. This hands-on display will allow exhibition visitors to view different production methods for their individual production needs. All of the stations displayed can be mounted to a range of standardized machine bases for varying line speed formats.

For 40 years the company has been manufacturing aerosol filling systems, and has been heavily involved in barrier and compartmental aerosol filling systems for over 25 years. In addition to their equipment for the filling of traditional aerosols, they offer filling systems for every type of barrier aerosol product in the industry today.

As a full line supplier of aerosol and filling equipment, Terco offers a complete range of ancillary equipment including: can feeding, conveyors, water bath test tanks, container accumulators, tip placers, overcap placers, pressure testers, propellant handling systems, safe filling rooms, and puck handling equipment.

Terco, Inc., located in Bloomingdale, IL USA, offers a worldwide technical sales and support network that includes global stocking of spare parts. With customers in over 45 countries the company has a reputation for offering dependable and flexible filling solutions.

See also:

What is Bag-On-Valve (BOV) Aerosol Filling?

Why use BOV Bag-On-Value Aerosol Filling?

Terco, Inc.

459 Camden Drive

Bloomingdale, IL 60108

USA

Phone: [+1] (630) 894-8828

Fax: [+1] (630) 894-8846

Contact: Bernie Brokke sales@terco.com

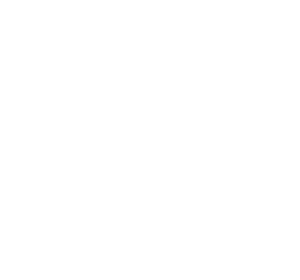

Gripper Water Bath

TERCO GRIPPER WATERBATH

The Gripper Waterbath has been designed for use with aerosol containers of various materials. The gripper style clips allow for the testing of tinplate, aluminum, plastic and glass containers.

The stainless steel carriage chain is configured with internal grippers as a standard. External grippers are available at no additional charge, but must be specified at time of order placement.

The system features a continuous motion rotary base for the loading and unloading of containers. The base is constructed from epoxy coated, structural steel and clad in polished stainless steel. The base is outfitted with an automatic chain tensionor for the carriage chain to ensure smooth and consistent container handling.

The tank section is constructed from polished stainless steel and supported by an epoxy coated, structural steel frame. The outer portions of the tank can be insulated with foam and clad in polished stainless steel.

Both the rotary base and the tank are secured with a safety enclosure that is interlocked into the machines drive logic. The doors of the enclosure are mechanically secured during normal operation and can only be accessed when the machine is not in ‘run’ operation. The enclosure is constructed with a clear anodized, aluminum frame and glass door panels. An exhaust vent port is configured over the tank section.

The carriage system that transports the cans through the tank is outfitted with an automated lifting system. In the event that a line stoppage occurs, the containers will automatically be lifted from the water. When returned to the water, the cans are held in a pre-set dwell time before continuing to transport through the machine.

Over the discharge transfer conveyor is a side blow-off assembly to remove residual water from the sides and top of the can and the cup section of the aerosol valve. It comes complete with a turbine blower rated for a hazardous location

Terco, Inc.

459 Camden Drive

Bloomingdale, IL 60108

United States

Phone: [+1] 630-894-8828

Fax: [+1] 630-894-8846

Contact: Bernie Brokke sales@terco.com