Bag-On-Valve Manufacturing

Terco manufactures the most reliable bag-on-valve machines in the world. With over 50 years of supplying the highest quality machinery, we have developed an experience base unmatched by others. To this we add our extensive engineering and manufacturing capabilities to allow a system to be configured that meets the exact needs of your application. Systems that are fully capable of meeting the needs of today and tomorrow.

How Does Bag-On-Valve Work?

Bag-on-Valve (BoV) technology is a form of aerosol packaging used in a variety of industries, ranging from food and beverages to cosmetics and medical supplies. The technology involves a flexible container that houses the product, with an airtight valve attached to the container. When the valve is pressed, a spray or foam is released from the container. The process works by creating a pressure difference inside and outside of the container.

When the valve is pressed, air is forced from outside of the container into the bag. This increase in pressure forces the product out of the container, creating a fine spray or foam. The advantage of this system is that it does not require any additional pressurization or propellants. This makes it a safe, economical and environmental friendly way to store and dispense products.

Overall, Bag-on-Valve technology is an efficient and safe way to package and dispense a variety of products. It provides an easy to use, cost-effective solution with no additional pressurization or propellants required. It is also highly environmental friendly, as it does not involve any hazardous chemicals or gases.

Contact Terco – The Bag-On-Valve Manufacturing Company

Bag On Valve Dispensing System

Bag on valve (BOV) aerosol filling is a packaging technology that has gained popularity over the years due to its unique benefits. It is a type of aerosol packaging that consists of a bag, which acts as the product container, and a valve, which acts as the dispenser. This technology offers several advantages over traditional aerosol packaging methods, making it a preferred choice for many products.

The BOV aerosol filling process begins by filling the bag with the product. The bag is then placed inside the aerosol can and sealed. The valve is then attached to the can, creating a seal between the bag and the valve. The valve is designed to dispense the product from the bag when it is pressed, allowing the product to be released in a controlled manner.

One of the main advantages of BOV aerosol filling is that it eliminates the need for propellants. Traditional aerosol packaging methods require the use of propellants, which can be harmful to the environment and health. BOV aerosol filling technology allows for products to be dispensed using air pressure, which is much safer and more environmentally friendly.

Another benefit of BOV aerosol filling is that it allows for products to be dispensed in any position. Traditional aerosol packaging methods require the can to be held in a specific position to dispense the product. BOV aerosol filling allows for the product to be dispensed in any position, making it easier to use and more convenient.

BOV aerosol filling technology is also ideal for products that are sensitive to air or moisture. The bag acts as a barrier, protecting the product from air and moisture, which can affect the product’s quality and efficacy. This makes it a suitable choice for products such as pharmaceuticals, cosmetics, and food products.

In addition, BOV aerosol filling technology allows for products to be dispensed more efficiently. The bag can be completely emptied, reducing product waste and increasing product yield. This is particularly important for high-value products, where even small amounts of waste can have a significant impact on profitability.

BOV aerosol filling technology has gained widespread acceptance in a variety of industries, including pharmaceuticals, cosmetics, and food products. Its unique benefits have made it a preferred choice for many manufacturers, who are seeking to enhance their product offerings while reducing their environmental impact.

In conclusion, BOV aerosol filling technology offers a range of benefits over traditional aerosol packaging methods. Its ability to eliminate the need for propellants, dispense products in any position, protect products from air and moisture, and increase product yield has made it a popular choice for many manufacturers. As technology continues to evolve, it is likely that we will see further innovations in this area, further enhancing the benefits of BOV aerosol filling technology.

Related Articles

WHAT IS BAG-ON-VALVE AEROSOL FILLING?

Bag-on-valve aerosol filling is the process of filling a flexible bag with a liquid or semi-liquid product and then sealing it inside a metal aerosol can along with a propellant. The bag is separated from the propellant by a valve, which controls the dispensing of the product.

The process typically involves several steps:

- The flexible bag is placed inside the metal can and the valve is attached to the top of the can.

- The product is then filled into the bag through a filling nozzle.

- The bag is then sealed and the can is filled with the propellant.

- The valve is then crimped onto the can to create an airtight seal.

The filling process is typically done using specialized equipment and automation to ensure accurate filling and consistent quality.

Once the can is filled, it is ready for dispensing. When the valve is actuated, the propellant pushes the product out of the bag and through the valve, dispensing it into the air as a fine mist or spray.

BOV aerosol filling technology is a versatile solution that can be used in a wide range of industries, including personal care, food and pharmaceuticals. Due to its consistent and controlled dispensing, it is ideal for products that require precise application, such as hair sprays, insect repellents and cooking oils.

What is bag on valve?

Bag-on-valve (BOV) is a packaging technology that allows for the dispensing of liquid and semi-liquid products in an aerosol can. The main component of a Bag-on-valve system is a flexible bag made of plastic, which is placed inside a metal can. The bag is separated from the propellant by a valve.

When the valve is actuated, the propellant, which is typically a compressed gas such as air or nitrogen, pushes the product out of the bag and through the valve. The product is then dispensed into the air as a fine mist or spray. Because the product is contained in a separate bag, it is not in direct contact with the propellant, which reduces the risk of contamination and allows for a longer shelf life.

BOV technology is commonly used for dispensing personal care products such as hair spray, sunscreen, and insect repellent. It is also used for food products like whipped cream, cooking sprays, and salad dressings.

One of the main advantages of BOV technology is that it allows for more consistent and controlled dispensing of the product compared to traditional aerosol cans. Because the product is not in direct contact with the propellant, the amount of product dispensed is not affected by changes in temperature or pressure. This means that the product is dispensed at a consistent rate, which is especially important for products that are used in precise applications like hair styling or cooking.

Another advantage of BOV is that it is more environmentally friendly than traditional aerosol cans. The metal cans used in BOV systems are recyclable and the flexible bags are made of plastic which can be also recycled.

In summary, Bag-on-valve is a packaging technology that allows for the dispensing of liquid and semi-liquid products in an aerosol can, with a flexible bag inside the can to separate the product from the propellant. This allows for consistent and controlled dispensing of the product and also it’s an environmentally friendly solution.

Efficient Aerosol Filling Machines for Streamlined Production

Efficient Aerosol Filling Machines for Streamlined Production

Specialized machinery known as aerosol filling machines is used to fill containers with aerosol products, which are usually pressurized and sprayed or misted finely. Numerous industries, such as the food and beverage, pharmaceutical, household goods, and personal care sectors, depend heavily on these machines. Due to the need for accuracy, efficiency, & adherence to strict safety regulations, aerosol filling technology has undergone significant development over time. Manufacturers are spending more money on cutting-edge filling technologies to increase production capacity as consumer demand for aerosol products keeps growing.

Key Takeaways

- Aerosol filling machines are used to fill aerosol products such as spray paints, deodorants, and air fresheners into cans or bottles.

- Key features of efficient aerosol filling machines include high filling accuracy, quick changeover between products, and minimal product wastage.

- Using efficient aerosol filling machines can lead to increased productivity, reduced production costs, and improved product quality.

- When choosing an aerosol filling machine, factors to consider include production capacity, filling accuracy, ease of maintenance, and compatibility with different aerosol products.

- Case studies have shown successful implementation of efficient aerosol filling machines leading to improved production efficiency and cost savings for companies.

- Future trends in aerosol filling machine technology include advancements in automation, integration of smart technology for real-time monitoring, and development of eco-friendly filling solutions.

A number of crucial procedures are involved in the aerosol filling process, such as product preparation, propellant and product filling, container sealing, & quality control standards compliance. Because of its intricacy, this process requires the use of advanced equipment that can work with a wide range of products, including liquids, powders, gels, and foams. Manufacturers hoping to maximize production lines and successfully satisfy consumer demands must comprehend the complexities of aerosol filling machines. A number of essential characteristics that improve their dependability and performance define efficient aerosol filling machines. The automation feature is among the most important ones. In order to reduce the need for manual intervention, modern machines frequently integrate automated systems that streamline the filling process.

By reducing human error and speeding up production, this automation guarantees consistent quality throughout batches. Fully automated systems, for example, can manage several filling stations at once, enabling increased throughput without sacrificing accuracy. The capability to manage different container sizes and shapes is another essential feature. Effective aerosol filling machines are made with movable parts that can hold a variety of cans and bottles, from tiny personal care items to bigger industrial uses. For producers of a wide variety of goods, this adaptability is crucial.

Also, many machines have sophisticated sensors and monitoring systems that give operators real-time information on pressure, filling levels, and other parameters. This information helps operators make well-informed decisions and adjustments throughout production. Using effective aerosol filling equipment has several advantages for producers. Enhanced productivity is one of the main benefits.

| Machine Type | Production Capacity | Filling Accuracy | Operational Speed |

|---|---|---|---|

| Automatic Aerosol Filling Machine | Up to 60 cans per minute | ±0.5% of filling volume | Adjustable, up to 100 cans per minute |

| Semi-Automatic Aerosol Filling Machine | Up to 30 cans per minute | ±1% of filling volume | Adjustable, up to 60 cans per minute |

Manufacturers can greatly cut cycle times and boost output by automating the filling process and improving machine performance. This is especially crucial in sectors where demand varies quickly because it enables businesses to react swiftly to shifts in the market without compromising quality. Also, effective aerosol filling equipment eventually results in cost savings.

Even though purchasing sophisticated machinery may require a large initial outlay, over time, the savings in labor expenses, waste, and product rework can result in sizable financial gains. For instance, automated systems frequently require fewer operators than manual filling lines, enabling businesses to more efficiently allocate their workforce. Precise filling also lessens the possibility of overfilling or underfilling containers, which minimizes product loss & guarantees regulatory compliance. In order to make sure that an aerosol filling machine fits the unique requirements of a manufacturing operation, a number of factors need to be considered. The kind of product being filled is one of the most important factors to consider.

Certain products have special qualities that call for particular handling methods. For example, a different filling mechanism might be required for viscous liquids as opposed to lighter sprays or foams. Comprehending the product’s attributes will assist manufacturers in selecting a machine that can provide the best possible performance. Production capacity is another important consideration. When choosing a machine, manufacturers need to consider both their present and future production volumes in order to avoid bottlenecks.

In addition to the machine’s speed, this entails assessing how well it can manage several product lines or variations. It is also important to take into account the production facility’s space limitations, as certain machines may need more floor space than others because of their configuration or design. Effective aerosol filling machines have been successfully installed by a number of businesses, increasing output & improving product quality. One prominent example is a well-known personal care company that encountered difficulties with its manual filling procedure. The business made the decision to purchase a fully automated aerosol filling line that could process several product formulations at once. They were able to maintain strict quality control procedures while experiencing a 50% increase in production speed as a result.

Also, the new system made it possible to monitor filling parameters in real time, allowing for prompt adjustments that further improved performance. The food industry provides another example, where a cooking spray manufacturer aimed to increase production efficiency. The company was able to cut its cycle time by 30% by switching to a high-speed aerosol filling machine with cutting-edge propellant integration technology. Along with improving output, this upgrade also decreased waste during the filling process & improved product consistency. By successfully implementing this technology, the manufacturer was able to increase the range of products it offered while upholding strict safety and quality standards. Innovation and shifting consumer needs are expected to propel major advancements in aerosol filling machine technology in the future.

Incorporating Industry 4.0 principles into aerosol filling operations is one new trend. Using IoT (Internet of Things) devices to collect and analyze data in real time during the production process is one example of this. Manufacturers can improve maintenance schedules, pinpoint possible problems before they become serious, and obtain insights into machine performance by utilizing data analytics. Also, aerosol filling technology is increasingly focusing on sustainability. Manufacturers are looking for ways to cut waste & their carbon footprint as environmental concerns increase.

This has prompted the creation of recyclable packaging materials and environmentally friendly propellants that satisfy consumer demands for sustainable goods. Features like systems made for simple cleaning & maintenance or those that make use of energy-efficient technologies may be incorporated into future aerosol filling machines to support these sustainable practices. In conclusion, aerosol filling machines are essential to many sectors of the economy where accuracy and efficiency are critical. In order to stay competitive in a market that is constantly changing, manufacturers need to keep up with the latest developments in machinery design and functionality.

FAQs

What is an aerosol filling machine?

An aerosol filling machine is a specialized piece of equipment used to fill aerosol cans with various products such as paints, lubricants, foams, and other pressurized substances.

How does an aerosol filling machine work?

Aerosol filling machines typically work by first pressurizing the can with propellant, then filling it with the desired product, and finally sealing the can with a valve and actuator.

What are the different types of aerosol filling machines?

There are various types of aerosol filling machines, including semi-automatic machines, fully automatic machines, and rotary indexing machines, each with different levels of automation and production capacity.

What are the benefits of using an aerosol filling machine?

Using an aerosol filling machine can increase production efficiency, ensure accurate filling and sealing, reduce product waste, and improve overall product quality and consistency.

What industries use aerosol filling machines?

Aerosol filling machines are used in a wide range of industries, including automotive, household products, personal care, pharmaceuticals, and industrial applications.

Innovative Packaging Solution: The Bag on Valve Aerosol Filling Machine

The bag on valve aerosol filling machine is a revolutionary method for packaging products with propellant, creating airtight seals between the product pouch and aerosol valve. This unique system allows for clean, hygienic, and leak-free dispensing.

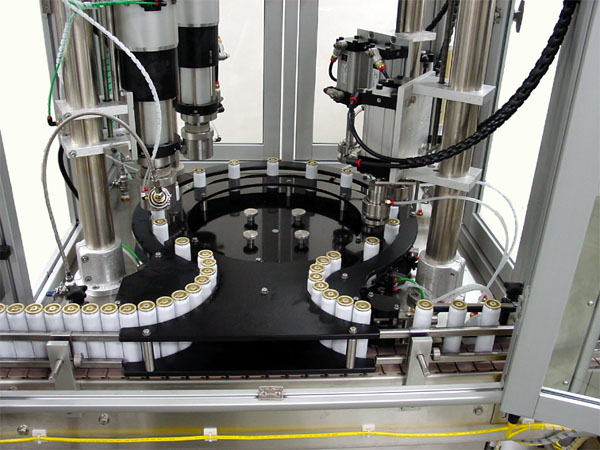

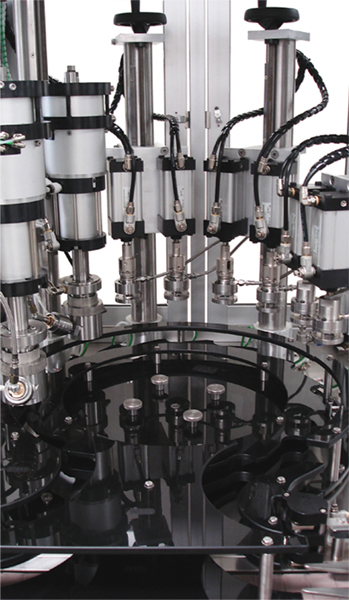

Parts and Operational Concept Of BoV Machines

The product reservoir, the propellant gas chamber, the valve crimping system, and the nozzle are some of the key parts of the bag-on-valve aerosol filling machine.

These devices operate on the basis of the product being placed inside a flexible bag and sealing it hermetically. The bag is enclosed in a rigid aerosol can with a valve attached to the top.

Strict safety and quality requirements are met by the bag on the valve filling machine.

Types of Bag on Valve Aerosol Filling Machines

There are three types of bag on valve aerosol filling machines to choose from, depending on your production scale and requirements.

- Manual filling machines, ideal for small-scale production, involve manual loading and sealing of bags.

- Semi-automatic filling machines are suitable for medium-sized production lines, automating some processes while still requiring human operators for specific tasks.

- Fully automatic filling machines are designed for high-volume production, fully automating the entire filling process from bag insertion to valve crimping.

Choose Efficiency and Quality with the Bag on Valve Aerosol Filling Machine

Armed with this information, select the perfect bag on valve aerosol filling machine for your specific needs and ensure top-notch packaging for your valuable product. Let this innovative technology take your packaging to the next level.

Suppliers of the Bag on Valve Filling Machine

Several distinguished manufacturers offer cutting-edge bag-on valve-filling machines with advanced technology and innovative features. Some notable suppliers include Terco, Inc. renowned for their dependable and efficient systems.

Manufacturers gain a competitive edge by offering products with better user experiences, longer shelf lives, and environmentally friendly packaging. Adopting this innovative technology creates new opportunities for a variety of industries, including pharmaceuticals and cosmetics. It ensures optimal product protection and precise, controlled dispensing. Choosing an automatic, semi-automated, or manual bag on valve filling machine is just one option for the bag on valve approach, which provides packaging solutions that are both customer-focused and sustainable.

Contact Terco about Your Bag on Valve Needs

Can You Spot The Bag On Valve Spray Can Technology?

A ground-breaking innovation in the aerosol product industry is Bag on Valve (BoV). This creative use of spray packaging is revolutionizing the way we use commonplace products, such as household cleaners and personal care items. Can you recognize a BoV product when you see one, though? Let’s look into the realm of bag on valve technology and examine its advantages, uses, and the reasons why both manufacturers and consumers are starting to favor it over other traditional aerosol can-filling technology.

What Does Bag on Valve Mean?

In aerosol cans, Bag on Valve technology is a novel packaging method that keeps the product and propellant apart. BoV employs a flexible bag inside the can to hold the product, as opposed to conventional aerosol packaging, which mixes the product with the propellant. The area between the bag and the can wall contains the propellant. The propellant expands when the actuator is pressed, squeezing the bag and releasing the product through the valve.

Bag on Valve Benefits

BoV technology offers several noteworthy benefits.

- Environmental friendliness: By using nitrogen or compressed air as propellants, BoV systems can reduce their reliance on hazardous chemicals.

- Product integrity: The purity and uncontaminated nature of the contents are guaranteed by the separation of the product and propellant.

- Total evacuation: Customers can use almost all of the product, which minimizes waste.

- Uniform spray performance is ensured throughout the product’s life by the system, which keeps up pressure until the very last drop.

- Spraying in multiple positions: BoV cans function well at any angle, even when turned upside down.

- Increased shelf life: The product is shielded from oxidation and contamination by the hermetically sealed bag.

- Safety: The likelihood of mishaps is decreased by the non-flammable propellants utilized in BoV systems.

Never Fall for Other Spray Products’ Tricks

Even though BoV technology has many advantages, not all spray products on the market make use of this cutting-edge system. Although conventional aerosol cans may have a similar exterior, they do not have the benefits of BoV. Here’s how to distinguish between the two:

- Examine the label: The packaging of many BoV products prominently features the company’s technology.

- Look at the spray: BoV products usually result in a more uniform, finer mist.

- Apply from various angles: BoV sprays function well in any orientation, but conventional aerosols might have trouble when inverted.

- Feel the temperature: Because the propellant doesn’t mix with the product, BoV cans frequently feel less cold when sprayed continuously.

- Pay close attention: Compared to the more abrasive noise made by conventional aerosols, BoV sprays frequently make a softer sound.

Examples of Spray Can Filling Bag on Valve Products:

BoV technology is used in a wide range of products and industries.

Pharmaceutical products: The sterile environment that BoV provides is beneficial for topical medications, wound care solutions, and nasal sprays.

Personal care products: BoV is used in sunscreens, hair sprays, and deodorants because it can dispense the product in a fine mist without the need for chemical propellants.

Food products: BoV’s capacity to guarantee product freshness and reliable dispensing is utilized by whipped cream and cooking sprays.

Cleaners for the home: The spray angle and uniform application of the system make it ideal for use with fabric refreshers and all-purpose cleaners.

Industrial products: BoV is used in paints and lubricants because it dispenses products accurately and completely.

In summary

Spray packaging has advanced significantly thanks to Bag on Valve technology. It is a better option for many applications due to its advantages for manufacturers, consumers, and the environment. Look for BoV products as you browse the aisles of your neighborhood store; they’ll probably improve user satisfaction while being less harmful to the environment.

Customers can make better decisions about the things they buy and use on a daily basis by being more knowledgeable about BoV products and how to choose them. We may anticipate even more cutting-edge uses for this technology in the future, further altering the aerosol packaging industry, as demand for it rises. Thus, consider this the next time you grab a spray can: Is it a bag on valve spray can?

Written as a service by Evolution Point, a Chicago Marketing Agency.

How To Choose Aerosol Filling Companies

Are you considering hiring aerosol filling companies to assist with the machine installation and design for filling your products? The quality, effectiveness, and commercial success of your product can all be greatly impacted by your choice of company. All aerosol products—household cleansers, cosmetics, or industrial solutions—need to be carefully formulated and packaged. Here is a thorough guide to assist you in making this crucial decision.

Related Articles:

- Skill and Knowledge

The key is experience. Businesses with a long history of aerosol filling have accumulated a wealth of knowledge in a variety of product categories and strong problem-solving techniques. When assessing a potential partner, take into account how long they have been in business and their experience with products similar to yours. Their specialized knowledge can assist you in streamlining the production process and avoiding common pitfalls. - Compliance and Quality Assurance

Ensuring quality is crucial. Comprehensive quality control systems should be possessed by a trustworthy aerosol filling company. Seek for certifications such as ISO 9001, which attest to compliance with global quality management standards. Make sure they abide by all applicable national and international laws. The EPA for household products and the FDA for personal care products are two examples. - Technological Abilities

The aerosol filling company’s technology has a big impact on the effectiveness and quality of their output. Among the benefits of contemporary, automated filling lines are consistency, decreased waste, and quicker turnaround times. Ask about the company’s filling technology types, capacities, and handling capabilities for various formulations and packaging styles.

Customization of the aerosol filling process is essential. Should you require particular propellants, fill volumes, or unique packaging designs, the company ought to be able to customize their services to meet your requirements. Another crucial factor is production volume flexibility. The business must be able to adjust its operations to meet your needs, whether they are for large-scale distribution or small batches for specialized markets. This flexibility guarantees that they can satisfy your needs no matter how they change over time. - Support for Formulation and R&D

Having assistance with formulation and research and development (R&D) can be a game-changer for businesses creating new products. Before starting large-scale production, some aerosol filling companies assist clients in developing and testing new formulations to make sure they are safe and effective. With this support, you can refine your product under the guidance of experts and save a significant amount of time and money. Additionally, it guarantees that the finished product satisfies all requirements and performs admirably in the marketplace. - Support for Logistics and Supply Chain

Timely production and distribution depend on effective supply chain management and logistical assistance. A reputable aerosol filling business should have solid connections with propellant, packaging, and raw material suppliers. In addition, they ought to provide logistical services like distribution, inventory control, and warehousing. This reduces delays and disturbances and guarantees a smooth production to market process. Maintaining lead times and product availability through effective logistics is essential for upholding customer satisfaction and competitiveness in the market. - Communication and Customer Service

A successful partnership requires excellent customer service and effective communication. When it comes to handling any problems or concerns that may come up, the aerosol filling company should be prompt, open, and proactive. A dedicated account manager, open channels of communication for feedback, and regular updates on production status can all greatly improve your experience. Good customer service builds a cooperative and happy relationship by guaranteeing that any problems are promptly fixed and that you are always aware of the status of your project. - Standing and Evaluations

Lastly, find out how the business is known in the sector. Seek endorsements and reviews from other companies that have collaborated with them. It’s more likely that a business that has a solid reputation for dependability, quality, and customer service will live up to your expectations. A company’s standing and performance may also be indicated by accolades and recognitions from the industry. A well-known business will probably be more reliable and competent, giving you faith in their ability to meet your needs.

Selecting the best aerosol filling business involves assessing their background, skills, and working methods. You can guarantee a partnership that produces high-quality products effectively and economically by concentrating on elements like quality assurance, technological prowess, customization options, and customer service. Maintaining a strong market presence and achieving product success require this meticulous selection process. In the long run, a successful and seamless production experience can be achieved by taking the time to carefully evaluate possible partners.

Bag On Valve Technology Shows Outstanding Advantages

The market has witnessed a rapid growth of Bag on Valve (BOV) technology these years, especially in the field of pharmaceutics, personal care, and household care.

Other Articles You Might Be Interested In:

Bag on valve technology shows its outstanding advantages in many aspects. It can isolate the product from the propellant gas, thus prolonging the shelf life dramatically. It uses non-flammable gas(Nitrogen or compressed air) as the propellant gas, which is much safer than the traditional aerosol technology. It is also able to eliminate the deterioration of product quality caused by the loss of solvent and decomposition of propellant.

It has been widely used in personal care, household care, food and beverage, pharmaceutics, etc.

The first Bag on valve technology was developed in Japan in the 1990s, and then it got very popular in Asia. It is still expanding rapidly in the European market. As a leader in this field, Nidec-Mitsui developed BOV technology for various industries (pharmaceuticals, cosmetics, etc.) over 10 years. The company based on its own rich experience and latest technologies proposed a wide range of BOV products to satisfy various needs of customers. Nidec-Mitsui’s BOV products are now exported to more than 50 countries/regions around the world with a high reputation among customers for their excellent quality and competitive price.

Pressure-free spray container (PFS) is a new type of spray container which has two parts: the bottle and the cap. The bottle is made of high-quality transparent material, such as polypropylene(PP), polyethylene(PE), polystyrene(PS), or polycarbonate (PC). The cap has a valve for controlling the spray direction. It is pressurized by air or nitrogen, which makes the liquid inside it be sprayed out through the valve. This kind of spray container can be used in all kinds of applications that are normally carried out with aerosol cans, such as household care products, personal care products, food products, etc. Thanks to its pressure-free design and other unique features, it offers many advantages over traditional aerosol cans.

Bag on Valve technology provides an excellent solution to many issues regarding aerosols. It eliminates all problems related to conventional aerosols. See Terco’s superior implementation of Bag on Valve BOV aerosol machines.

Bag on Valve Aerosol Filling Machines

Bag on Valve (BoV) technology has revolutionized the aerosol packaging industry. This ground-breaking technology changed product packaging by fusing sustainability and convenience.

But what makes BoV unique? Picture your product securely enclosed in a pliable bag that is fastened shut with an advanced valve. This clever filling method ensures that your products reach customers in perfect condition by improving product protection and extending shelf life.

BoV has a striking effect on manufacturers. Modern bag on valve filling machines allow businesses to package a wide range of products, from pharmaceutical wonders to personal care wonders, with ease.

Still, that’s not all! Businesses that embrace the bag on valve filling machine also embrace sustainability, which is important to today’s consumers. By partnering with environmentally friendly packaging options, your business attracts customers and makes a splash in a market that is eager to buy green products.

Join the leaders in the industry and make a splash with this alluring, innovative, and ecologically beneficial method by embracing the future of aerosol filling. The bag on valve filling process has revolutionized aerosol packaging.

Advantages of Bag on Valve Packaging

- Bag on Valve (BoV) packaging provides maximum product protection with an extended shelf life. Manufacturers looking to preserve the quality of their products finds this technology advantageous.

- BoV technology is an eco-friendly option. It has a significantly smaller environmental impact than traditional aerosol packaging, demonstrating a commitment to environmental responsibility.

- The valve filling machine’s bag ensures accurate product dispensing, making controlled dispensing simple and reliable. This improves user experience and lowers product waste.

- BoV is a versatile packaging solution. It is used in a wide range of consumer products, including food, pharmaceuticals, personal care and household items.

- The bag on valve aerosol filling machine packaging conforms to strict regulations and safety standards. It ensures consumer safety and product integrity. Manufacturers are adopting the bag on valve filling machine due to its efficacy.

- Modern bag on valve aerosol filling equipment can help businesses improve productivity, expedite the manufacturing process, and meet customer expectations more rapidly.

- Producers can improve product performance and quality with the bag-on valve filling machine, which will increase customer satisfaction and brand loyalty.

- The sophisticated technology of the valve filling machine’s bag guarantees accurate and airtight valve crimping, which is essential for preserving product freshness and averting leaks.

- BoV packaging is a packaging method that give consumers’ growing demand for sustainable and eco-friendly packaging options.

- Manufacturers using bag on valve packaging obtain a competitive advantage in a fiercely competitive market by providing innovative, aesthetically pleasing, and eco-friendly solutions.

- The bag on valve filling machine revolutionizes packaging and offers producers and consumers a number of environmentally friendly advantages. It is popular for a range of products due to its extended shelf life, reduced environmental impact, precise dosage, and regulatory compliance.

- Manufacturers may embrace sustainability and technical improvements while preserving product quality and successfully satisfying client demands by investing in the bag on valve aerosol filling machine.

Innovative Packaging Solution: The Bag on Valve Aerosol Filling Machine

The bag on valve aerosol filling machine is a revolutionary method for packaging products with propellant, creating airtight seals between the product pouch and aerosol valve. This unique system allows for clean, hygienic, and leak-free dispensing.

Parts and Operational Concept Of BoV Machines

The product reservoir, the propellant gas chamber, the valve crimping system, and the nozzle are some of the key parts of the bag-on-valve aerosol filling machine.

These devices operate on the basis of the product being placed inside a flexible bag and sealing it hermetically. The bag is enclosed in a rigid aerosol can with a valve attached to the top.

Strict safety and quality requirements are met by the bag on the valve filling machine.

Types of Bag on Valve Aerosol Filling Machines

There are three types of bag on valve aerosol filling machines to choose from, depending on your production scale and requirements.

Manual filling machines, ideal for small-scale production, involve manual loading and sealing of bags.

Semi-automatic filling machines are suitable for medium-sized production lines, automating some processes while still requiring human operators for specific tasks.

Fully automatic filling machines are designed for high-volume production, fully automating the entire filling process from bag insertion to valve crimping.

Choose Efficiency and Quality with the Bag on Valve Aerosol Filling Machine

Armed with this information, select the perfect bag on valve aerosol filling machine for your specific needs and ensure top-notch packaging for your valuable product. Let this innovative technology take your packaging to the next level.

Suppliers of the Bag on Valve Filling Machine

Several distinguished manufacturers offer cutting-edge bag-on valve-filling machines with advanced technology and innovative features. Some notable suppliers include Terco, Inc. renowned for their dependable and efficient systems.

Manufacturers can gain a competitive edge by offering products with better user experiences, longer shelf lives, and environmentally friendly packaging with the bag on valve aerosol filling machine.

Adopting this innovative technology creates new opportunities for a variety of industries, including pharmaceuticals and cosmetics, as it ensures optimal product protection and precise, controlled dispensing. Choosing an automatic, semi-automated, or manual bag on valve filling machine is just one option for the bag on valve approach, which provides packaging solutions that are both customer-focused and sustainable.

The Bag on Valve Filling Process: A Step-by-Step Guide

When it comes to the bag on-valve filling procedure, product preparation, gas selection, and filling all play important roles. These crucial elements are key to ensuring the precise and effective packaging of various items using a sophisticated bag on valve aerosol-filling machine.

Step 1: Product Preparation

First, a specially designed laminated bag is filled with the desired goods, serving as the primary container for the product.

Step 2: Hermetic Sealing

Next, the bag is hermetically sealed to prevent any interaction between the product and the propellant or outside environment.

Step 3: Assembly

The sealed bag is then placed inside the aerosol can, which serves as the secondary container. A dip tube-equipped aerosol valve is crimped onto the can to ensure a secure fit.

Step 4: Pressurization

Once assembled, an appropriate propellant is used to pressurize the aerosol can.

Step 5: Dispensing

When the customer depresses the actuator, the propellant forces the product through the dip tube and valve, effectively dispensing it from the bag.

Benefits of Bag on Valve Filling

Complete product evacuation is made possible by the bag on valve filling method, which reduces waste and maximizes utilization. The risk of contamination is removed by separating the product from the propellant, protecting the integrity of the product and prolonging its shelf life. Bag on valve technology’s adaptability also helps manufacturers by making it appropriate for a variety of uses, such as household goods, medications, and personal care products.

Gas Selection: A Crucial Step

The success of the bag on valve filling process relies heavily on the appropriate gas selection. Manufacturers carefully choose the gas based on product requirements, such as propellants for foaming products or inert gasses for sensitive formulations. The selected gas plays a crucial role in effectively dispensing the product and maintaining its integrity.

Valve Crimping and Sealing Techniques

Once the product and gas are combined, the next step is valve crimping. Its purpose is to securely attach the valve to the bag, preventing any potential leakage or contamination. To ensure consistency and efficiency in production, advanced bag on valve aerosol filling machines utilize automated crimping techniques. Additionally, proper sealing techniques are implemented to safeguard the product and maintain its shelf life.

Quality Control during Filling

Throughout the filling process, stringent quality checks are employed. Constant monitoring of weight and pressure measurements guarantees consistent product quantities and can integrity, ensuring that the final product meets safety standards.

The filling process entails placing the product in the bag and then positioning it inside the aerosol can. The crucial valve crimping step prevents any leakage, while the choice of propellant gas plays a significant role in the product’s performance.

Careful quality control measures are integrated throughout the entire process. Specialized equipment and machinery are utilized to ensure precise filling and to maintain the integrity of the finished product. The bag on valve filling machine presents manufacturers with various benefits, including improved user experience, increased shelf life, and environmental friendliness.

For businesses seeking to be environmentally and consumer-friendly, the bag on valve filling machine offers a robust alternative to conventional aerosol packaging. This cutting-edge technology has widespread application in multiple sectors, from personal care to medicine and home goods. Embracing this technology can help companies achieve a more eco-friendly and productive future.

Innovative Uses of Bag on Valve Technology

The bag on valve technology is being adopted by numerous industries, most notably the personal care and cosmetics sector. Manufacturers have recognized and implemented the benefits of using a bag-on-valve aerosol filling machine when packaging products like sunscreen and hair sprays. Customers are guaranteed a continuous and precise spray, enhanced product protection, and a reduction in contamination concerns with this cutting-edge technique.

The medical and pharmaceutical industries now acknowledge the advantages of bag-on-valve packaging. The bag hermetic seal of the valve aerosol filling machine extends the shelf life and preserves the sterility of the product, particularly for sensitive ingredients like wound washes, nasal sprays, and saline solutions. Increased reliability and safety are now advantages for products intended for patients and medical professionals.

In the food and beverage industry, bag on valve technology is quickly becoming a practical and hygienic packaging option. It is now possible to package items like whipping cream, cooking sprays, and oil mists using the bag on valve aerosol filling machine. This procedure ensures that the product’s quality and freshness are maintained while providing countless creative opportunities.

The home and business sectors have shown how versatile bag on valve technology is. In order to ensure controlled dispensing and minimize waste, cleaning agents, lubricants, and insect repellents are now packaged in bags on valve filling machines. The product’s effectiveness is maintained by the hermetically sealed bag, which prevents dangerous chemical reactions.

Thanks to the adoption of a bag on valve aerosol filling machine, manufacturers can now provide better products with a longer shelf life, a smaller environmental impact, and an improved user experience.

Bag on valve packaging has become a popular choice for businesses producing food, household goods, pharmaceuticals, personal care products, or other products that require innovative and sustainable packaging solutions.

Advantages for Manufacturers: Economical and Effective Production

The bag on valve filling machine offers a practical and economical way to package goods. Its efficient workflow lowers operating costs by minimizing production downtime and reducing material waste. These machines boost production efficiency, generating higher output while preserving product quality, with faster filling cycles and automated controls.

Market positioning and brand differentiation

By providing a distinctive packaging format, the bag on valve technology helps manufacturers stand out in a very competitive market. This creative aerosol packaging system gives products a perceived value boost, grabbing customers’ attention and offering fresh, practical solutions.

Consumer Preference and Demand for Sustainable Packaging

As consumers prioritize environmentally-friendly packaging, the bag on valve filling machine meets their needs by replacing toxic CFCs or hydrocarbon propellants with compressed air or nitrogen as propellants.

Using eco-friendly packaging makes a brand more palatable to consumers who care about the environment and strengthens its reputation for moral business conduct. Manufacturers can become industry leaders and gain a competitive edge by implementing bag on valve technology.

Comparison with Traditional Aerosol Packaging

BoV and Conventional Aerosols: A Comparative Analysis

Compared to conventional aerosol packaging, bag on valve filling machines use different technology. Propeller and product are kept apart in bag on valve systems until the product is distributed, preventing any possible chemical reactions and guaranteeing product integrity.

Conventional aerosols, on the other hand, combine the material and propellant, raising the possibility of chemical reactions and shortening the product’s shelf life.

Regulatory Aspects and Environmental Effects

Vacuum filling machines with bags on valves are a more environmentally friendly option. Strict environmental regulations are met by these cans since they don’t contain any hazardous CFCs or other ozone-depleting materials. Traditional aerosols, on the other hand, release propellants that are difficult to recycle and may be harmful to the environment.

Comparison of User Experience and Performance

Better performance and user experience are offered by the bag on valve aerosol filling machine. BoV technology ensures precise application and reduces waste by providing a consistent and controlled spray pattern. On the other hand, irregular spray patterns in conventional aerosols can result in inefficiencies and disgruntled customers.

Comparing the bag on valve filling machine to conventional aerosol packaging, there are a number of benefits. Propeller and product are kept apart to ensure longer shelf life and product integrity. It also offers an easy and effective spraying experience while adhering to current environmental regulations. It is therefore a very appealing option for businesses searching for a cutting-edge, eco-friendly packaging solution.