- Home

- News & PR

Bag on Valve (BoV) technology has revolutionized the aerosol packaging industry. This ground-breaking technology changed product packaging by fusing sustainability and convenience. But what makes BoV unique? Picture your product securely enclosed in a pliable bag that is fastened shut with an advanced valve. This clever filling method ensures that your products reach customers in perfect condition by improving product protection and extending shelf life. BoV has a striking effect on manufacturers. Modern bag on valve filling machines allow businesses to package a wide range of products, from pharmaceutical wonders to personal care wonders, with ease. Still, that’s not all! …

Aerosol cans are a common strategy to provide a wide run of items – from life-saving inhalers to antiperspirants. However, have you ever considered how these machines are made to fill these pressurized containers? Aerosol can filler machines are engineering and manufacturing marvels that hold the key to the solution. Other Articles You Might Be Interested In: Engineering and Manufacturing Aerosol Can Filler Machines Precision engineering is at the heart of an aerosol can filler machine. These machines meticulously handle various product phases – liquids, propellants, and gases – ensuring they are dispensed into the can in the correct sequence …

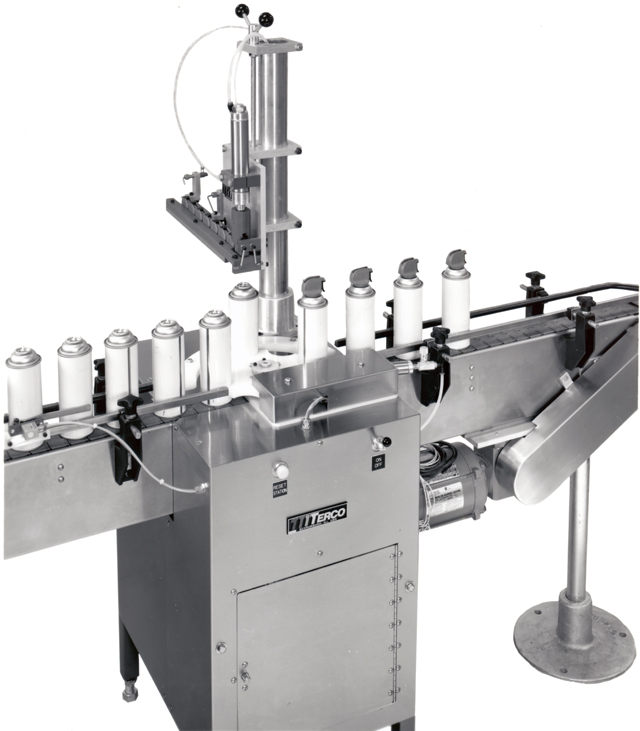

With a rich heritage spanning over five decades, our company specializes in the engineering and manufacturing of Terco’s aerosol filling equipment, catering to diverse applications. Our global footprint boasts the successful installation of over 2,500 aerosol machines, establishing our reputation for delivering high-quality equipment within remarkably short lead times. Our machinery portfolio encompasses a spectrum of options, ranging from low to high-speed equipment designed for aerosol and rotary liquid fill systems, rotary base crimpers, gasser/shakers, propellant and liquid fillers, and bag-on-valve (BOV) systems, among others. Catering to a diverse array of market segments, including health and beauty, coatings and sealants, …

In our ever-evolving world, packaging technology continues to push boundaries. One remarkable solution leading the way is the Bag-On-Valve (B.O.V.) aerosol system. Created for liquid and viscous products, this ingenious system has become a packaging game-changer. In this article, we’ll dive into the B.O.V.’s inner workings and explore its numerous advantages and applications across industries. How the Bag-On-Valve Aerosol Works The B.O.V. system’s concept is elegantly simple. It ensures a complete separation between the product and the propellant, usually eco-friendly air or nitrogen. This separation guarantees the product remains uncontaminated, maintaining its quality throughout its shelf life. This system is …

Terco manufactures the most reliable bag-on-valve machines in the world. With over 50 years of supplying the highest quality machinery, we have developed an experience base unmatched by others. To this we add our extensive engineering and manufacturing capabilities to allow a system to be configured that meets the exact needs of your application. Systems that are fully capable of meeting the needs of today and tomorrow. How Does Bag-On-Valve Work? Bag-on-Valve (BoV) technology is a form of aerosol packaging used in a variety of industries, ranging from food and beverages to cosmetics and medical supplies. The technology involves a …

Bag on valve (BOV) aerosol filling is a packaging technology that has gained popularity over the years due to its unique benefits. It is a type of aerosol packaging that consists of a bag, which acts as the product container, and a valve, which acts as the dispenser. This technology offers several advantages over traditional aerosol packaging methods, making it a preferred choice for many products. The BOV aerosol filling process begins by filling the bag with the product. The bag is then placed inside the aerosol can and sealed. The valve is then attached to the can, creating a …

Bag-on-valve aerosol filling is the process of filling a flexible bag with a liquid or semi-liquid product and then sealing it inside a metal aerosol can along with a propellant. The bag is separated from the propellant by a valve, which controls the dispensing of the product. The process typically involves several steps: The filling process is typically done using specialized equipment and automation to ensure accurate filling and consistent quality. Once the can is filled, it is ready for dispensing. When the valve is actuated, the propellant pushes the product out of the bag and through the valve, dispensing …

Efficient Aerosol Filling Machines for Streamlined Production Specialized machinery known as aerosol filling machines is used to fill containers with aerosol products, which are usually pressurized and sprayed or misted finely. Numerous industries, such as the food and beverage, pharmaceutical, household goods, and personal care sectors, depend heavily on these machines. Due to the need for accuracy, efficiency, & adherence to strict safety regulations, aerosol filling technology has undergone significant development over time. Manufacturers are spending more money on cutting-edge filling technologies to increase production capacity as consumer demand for aerosol products keeps growing. Key Takeaways A number of crucial …

Bag On Valve aerosol technology is a new way of packing your products. Are you looking for a packaging solution for your aerosol products? Such as cosmetic and beauty products, food products, pharmaceutical products, fire extinguisher etc. Or you just tired of using traditional aerosol packaging technology? Then why not try to use bag on valve aerosol technology to fix your packing issues? Conventional aerosol spray technology Conventional aerosol packaging combines three elements: BoV technology The Bag-on-Valve aerosol system is built around an aerosol spray valve welded to a sealed poly-laminated aluminum bag. When filled with product, the bag is …

Related Posts

- THE Rotary Indexing Machine

- How To Choose A Bag-On-Valve Manufacturer

- Spray Can Filler Machine

- Efficient Aerosol Filling Equipment for Your Production Needs

- Revolutionizing Aerosol Packaging with Bag on Valve Technology

- Understanding The Bag on Valve Aerosol Filling Machine

- Aerosol Can Filler Machines: How They are Made, What’s It’s Utilized For, and Why Terco Makes the Best Machines

- Terco’s Aerosol Filling Equipment: Elevate Your Production with Our Cutting-Edge Aerosol Filling Equipment Solutions

- Streamlining Production With Aerosol Filling Machines

- The Bag-On-Valve Aerosol System: A Packaging Marvel

- Bag-On-Valve Manufacturing

- Bag On Valve Dispensing System

- WHAT IS BAG-ON-VALVE AEROSOL FILLING?

- What is bag on valve?

- Efficient Aerosol Filling Machines for Streamlined Production

- Innovative Packaging Solution: The Bag on Valve Aerosol Filling Machine

- Can You Spot The Bag On Valve Spray Can Technology?

- How To Choose Aerosol Filling Companies

- Bag On Valve Technology Shows Outstanding Advantages

- Bag on Valve Aerosol Filling Machines

- Bag On Valve Aerosol

- Bag on Valve Aerosol Cans Versus Traditional Aerosol Cans

- LCN Series Dispensing Nozzle

- Bag-On-Valve Filling System

- Gripper Water Bath